Mechanical fastening is a fundamental joining method that allows components to be assembled and disassembled without damage. This course covers common fasteners, tools, standards, and best practices for achieving strong and durable joints.

- Teacher: GASPARD HARERIMANA

Bending is a metal forming process that shapes materials by applying force, causing plastic deformation where the outer surface stretches and the inner surface compresses. It is commonly performed on sheet metals, rods, and bars using machines like press brakes and roll benders. The process depends on factors such as material type, thickness, bend radius, and applied force. Accurate results require proper bend calculations and strict safety measures. Bending is widely used in manufacturing and construction to produce parts like brackets, frames, and panels.

- Teacher: GASPARD HARERIMANA

SMAW on mild steel involves using a flux-coated consumable electrode to create an electric arc between the electrode and the mild steel workpiece. The arc generates intense heat (around 3,000–6,000°C) that melts both the electrode and the base metal, forming a molten weld pool. As the weld cools, it solidifies into a strong joint.

- Teacher: OLIVIER MPARIBATENDA

Metal cutting is the process of removing material from a metal workpiece to give it a desired shape, size, or surface finish. This is usually done using a cutting tool that shears away small chips of metal. Metal cutting is an essential operation in manufacturing industries to create parts and components for machinery, vehicles, and equipment.

There are two main

- Teacher: OLIVIER MPARIBATENDA

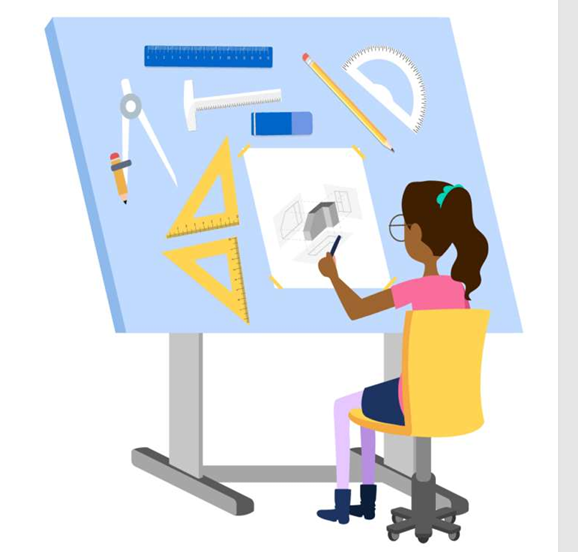

Technical drawing is a precise and detailed method of creating drawings that visually communicate how something functions or is constructed. It is commonly used in engineering, architecture, and manufacturing

- Teacher: OLIVIER MPARIBATENDA

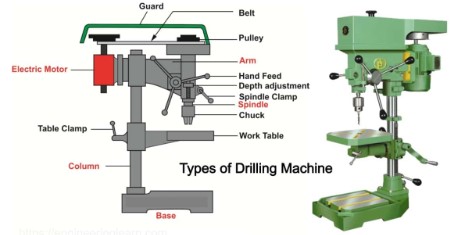

A drilling machine operation is the process of creating, enlarging, or finishing holes in a workpiece using a rotating cutting tool called a drill bit. The machine works by rotating the drill bit at high speed while applying downward pressure to cut into the material. Common operations performed include drilling, reaming, counterboring, countersinking, tapping, and spot facing. Drilling machines are widely used in metalworking, woodworking, and construction due to their accuracy, efficiency, and ability to produce holes of different sizes and depths.

- Teacher: Paulin NIYIGABA

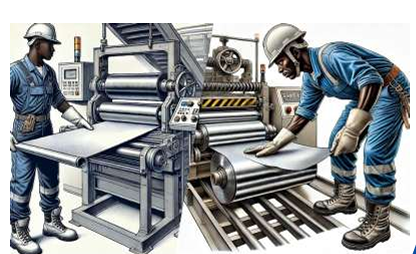

This module describe as a metal forming process in which a piece of metal is passed through one or more pairs of rotating rolls to reduce its thickness, make it uniform, and/or give it a desired cross-sectional shape

- Teacher: OLIVIER MPARIBATENDA

This course introduces the fundamental principles and practices of sand casting, one of the oldest and most widely used manufacturing processes for producing metal parts. Students will gain theoretical knowledge and practical skills in preparing sand molds, selecting suitable materials, pouring molten metal, and finishing cast products.

- Teacher: GASPARD HARERIMANA