Preventive Maintenance (PM) Level 4 is the most advanced and comprehensive stage in a multi-tiered PM program used in manufacturing technology. This level focuses on deep inspections, diagnostics, and overhauls to ensure long-term equipment reliability and performance. It often involves specialized personnel, advanced tools, and predictive technologies.

- Teacher: AUGUSTIN MBONIGABA

Assembly is the process of putting together individual manufactured parts or components to form a final product, sub-assembly, or system. It is a key phase in manufacturing and production.

- Teacher: AUGUSTIN MBONIGABA

cost estimation summary for Level Four Manufacturing Technology, focusing on advanced manufacturing processes such as precision assembly, testing, and final production stages. This analysis considers global best practices and emerging technologies in cost estimation.

- Teacher: AUGUSTIN MBONIGABA

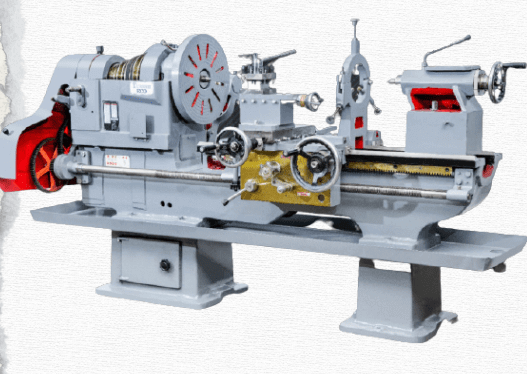

This course introduces learners to the lathe machine, one of the most important and widely used machines in manufacturing technology. Students will gain both theoretical knowledge and practical skills in operating, maintaining, and applying the lathe for different machining processes.

The course begins with the history, types, and parts of the lathe machine, explaining their functions and importance. Students will learn about the working principle, which is based on the rotation of the workpiece against a cutting tool to remove material.

- Teacher: Jeremie NGIZWENAYO