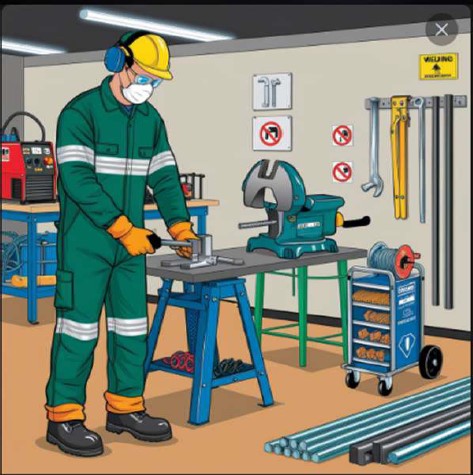

The SMAW on Aluminium, Stainless Steel and Cast Iron (MATSA401) module provides learners with the theoretical knowledge and practical skills needed to perform Shielded Metal Arc Welding (SMAW) on a variety of metals. The course emphasizes workplace preparation, including material selection, tool and equipment setup, and the application of safety measures. Learners develop competence in welding different metals specifically aluminium, stainless steel, and cast iron by applying appropriate SMAW techniques, cutting methods, and defect correction procedures to ensure high-quality welds. The module also covers finishing operations, such as surface treatment, product protection, storage, workplace cleaning, and technical reporting. By the end of the course, students will be able to safely and effectively weld, finish, and maintain products made from various metals, following industrial standards of quality and safety.

- Teacher: NIYITEGEKA Jean Damascene

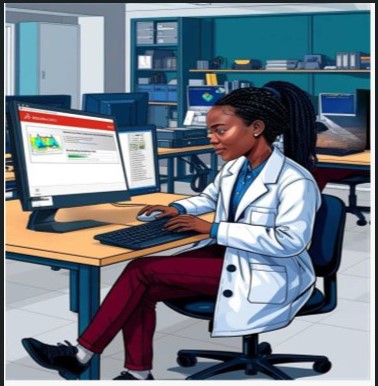

The Mould Pattern Making (MATMP401) module develops learners’ knowledge and practical skills in designing, producing, and finishing mould patterns for metal casting. It focuses on workplace preparation, task analysis, tool and material organization, and safety practices. Learners gain competence in pattern and core box design, moulding box fabrication and assembly, and the use of Computer-Aided Drafting (CAD) for precision work. The module also covers surface finishing, product protection, workplace maintenance, and technical reporting. By completion, learners can plan, fabricate, assemble, and finish mould patterns and boxes in line with industrial quality and safety standards.

- Teacher: NIYITEGEKA Jean Damascene

This course MATOA401: Oxy-Acetylene Gas Welding On Stainless Steel, Aluminium, and Cast Iron covers the fundamental skills and knowledge required for oxy-acetylene gas welding on stainless steel, aluminium, and cast iron. It is divided into three key learning outcomes. The first focuses on preparing the workplace, including organizing tools, materials, and equipment, and applying safety measures. The second covers welding techniques, from cutting and preparing the workpiece to setting the flame and performing various welds, including correcting defects. The third outcome involves finishing tasks such as grinding, polishing, protecting, storing the product, and cleaning the workspace. The course combines practical skills with essential safety and quality practices for effective gas welding operations.

- Teacher: |GIRINSHUTI Fabrice

Assembling manufactured parts or components is the process of joining individual parts to create a finished product or system. It involves fitting, aligning, and fastening parts together using methods such as bolting, welding, riveting, screwing, or adhesive bonding.

The main goal is to ensure the correct function, strength, and quality of the final product. Assembly can be done manually or automatically (using machines or robots) and often includes inspection and testing to verify accuracy and performance.

- Teacher: NIYITEGEKA Patrick

Spot welding is a resistance welding process used to join two or more metal sheets together by applying pressure and heat generated from an electric current at small points (spots). The metal surfaces are clamped between two copper electrodes, and when current passes through, the resistance at the contact points produces enough heat to melt and fuse the metals.

It is commonly used in automotive, sheet metal, and appliance manufacturing because it is fast, clean, and efficient. However, it is mainly suitable for thin metal sheets and not ideal for thick materials or non-metallic materials.

- Teacher: NIYITEGEKA Patrick

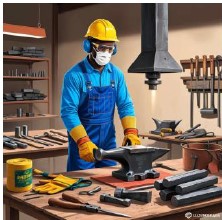

Forging is a manufacturing process where metal is shaped by applying compressive forces using tools such as hammers, presses, or dies. The process can be performed at high temperatures (hot forging) or at room temperature (cold forging)

- Teacher: NIYITEGEKA Patrick

- Teacher: NIYITEGEKA Patrick

Machine Preventive Maintenance is a proactive approach focused on ensuring that machines and equipment remain in optimal working condition. It involves regularly scheduled activities intended to prevent equipment failures and maintain operational efficiency.

- Teacher: |GIRINSHUTI Fabrice

In this module of Lathe Machine Operation, we will deal with the essential skills and knowledge required to operate a lathe machine effectively and safely. The module is divided into three key learning outcomes: preparing the workplace, carrying out turning operations, and completing finishing activities. Learners will explore topics such as organizing the workspace, selecting appropriate tools and materials, performing machining tasks, and applying proper safety and cleaning procedures. Each section includes hands-on activities and assessments to develop practical, job ready competencies. Overall, this module prepares trainees for real-world lathe operations with a strong focus on precision, efficiency, and workplace safety.

- Teacher: |GIRINSHUTI Fabrice