Enrolment options

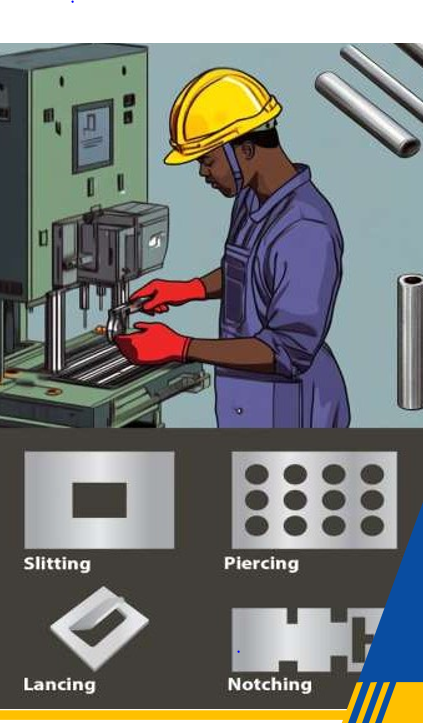

Punching operation is a type of press working process used in manufacturing where a tool (punch) is forced through sheet metal to remove a slug of material, creating a hole.

🔹 Purpose:

To create holes or cut-outs in sheet metal using a punch and die setup.

🔹 Basic Principle:

- A punch presses the sheet metal against a die.

- The punch shears the material and removes a portion (called a slug).

- The remaining material has a clean hole or profile.

🔹 Key Components:

- Punch – the tool that moves downward to cut the material.

- Die – supports the material and defines the shape of the hole.

- Sheet metal – the workpiece.

🔹 Types of Punching Operations:

- Blanking – the cut-out piece is the desired part.

- Piercing – the hole is the desired feature.

- Nibbling – series of small punches to make complex shapes.

- Perforating – punching multiple holes.

🔹 Applications:

- Automotive panels

- Electronic enclosures

- Metal brackets

- Kitchen appliances

🔹 Advantages:

- Fast and efficient

- High repeatability

- Cost-effective for large volumes

- Teacher: ALBERT IMANIRAFASHA