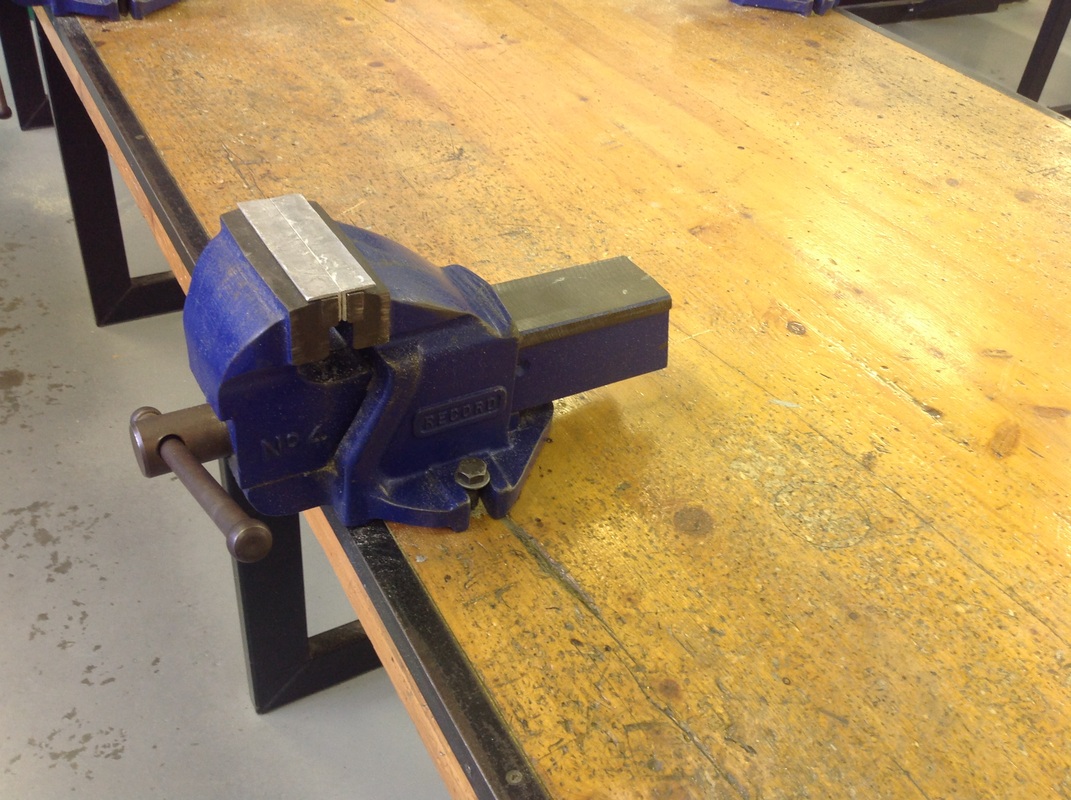

This course provides learners with the fundamental knowledge and practical skills required to perform benchwork operations in manufacturing and mechanical workshops. It emphasizes the correct use of hand tools, measuring instruments, and work-holding devices to produce accurate and quality components. Students will learn how to carry out basic operations such as filing, marking, sawing, drilling, tapping, threading, scraping, chiseling, and fitting.

- Teacher: ELIE NSENGIMANA

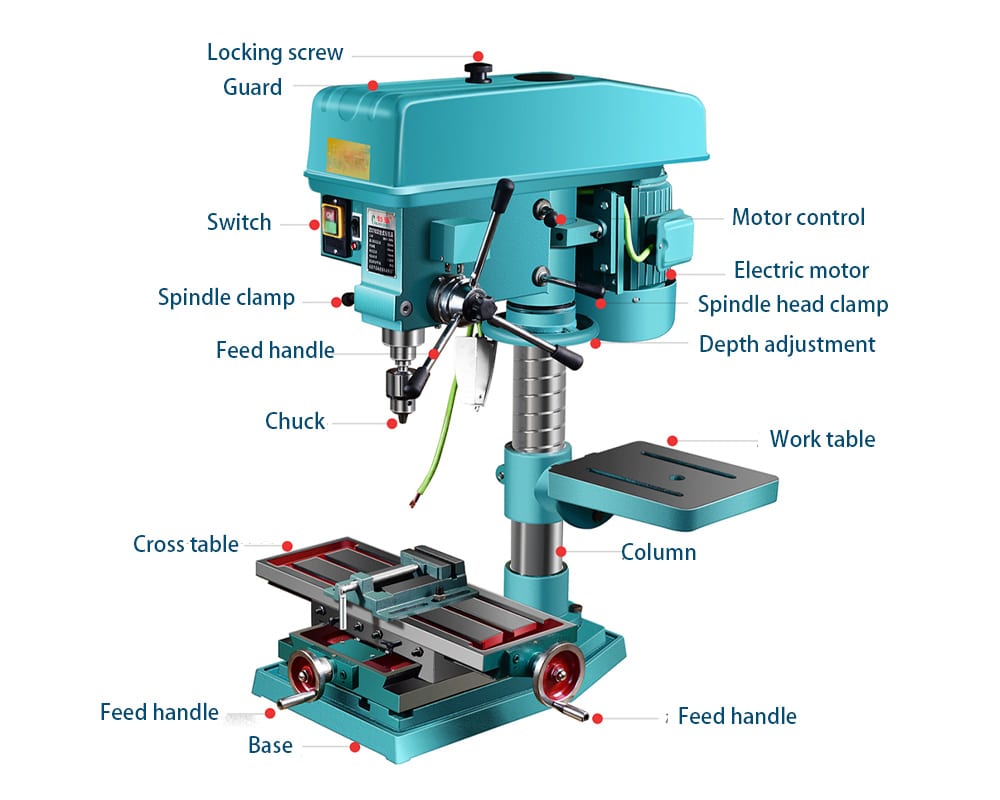

This course equips learners with both theoretical knowledge and practical skills required to operate drilling machines effectively and safely in a manufacturing environment. It focuses on understanding the working principles, types, tools, and operational techniques of drilling machines, while emphasizing industry-standard safety practices.

- Teacher: ELIE NSENGIMANA

This module describes employable and practicable skills, knowledge and right attitudes required by a learner to prepare tools, materials and equipment for mechanical fastening, Carry out mechanical fastening and Perform post-operation activities. The content provided in this course are package reserved for a learner pursuing TVET certificate III in manufacturing technology. Graduates at this level will have knowledge and skills for initial work, community involvement and/or further learning.

- Teacher: RAISSA IRADUKUNDA

Casting Process is a process in which hot liquid metal is poured into a mould that contains a hollow cut out or cavity of the desired finished shape. it is begins by creating a mould, which is the ‘reverse’ shape of the part we need. The mould is made from a refractory material, for example, sand. The metal is heated in an oven until it melts, and the molten metal is poured into the mould cavity. The liquid takes the shape of cavity, which is the shape of the part. It is cooled until it solidifies. Finally, the solidified metal part is removed from the mould.

- Teacher: Vedaste NDORUNKUNDIYE

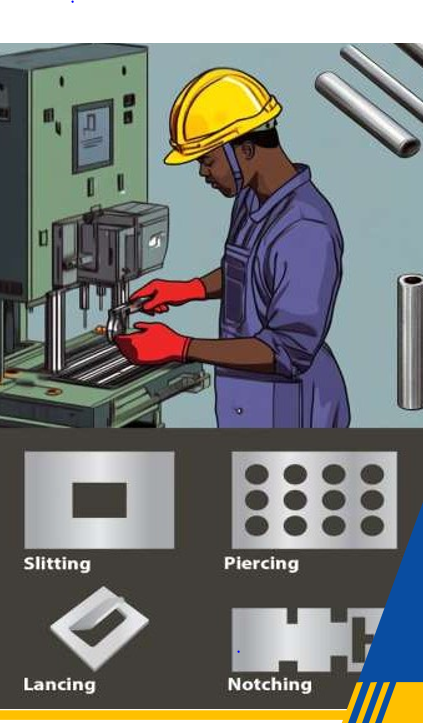

Punching operation is a type of press working process used in manufacturing where a tool (punch) is forced through sheet metal to remove a slug of material, creating a hole.

🔹 Purpose:

To create holes or cut-outs in sheet metal using a punch and die setup.

🔹 Basic Principle:

- A punch presses the sheet metal against a die.

- The punch shears the material and removes a portion (called a slug).

- The remaining material has a clean hole or profile.

🔹 Key Components:

- Punch – the tool that moves downward to cut the material.

- Die – supports the material and defines the shape of the hole.

- Sheet metal – the workpiece.

🔹 Types of Punching Operations:

- Blanking – the cut-out piece is the desired part.

- Piercing – the hole is the desired feature.

- Nibbling – series of small punches to make complex shapes.

- Perforating – punching multiple holes.

🔹 Applications:

- Automotive panels

- Electronic enclosures

- Metal brackets

- Kitchen appliances

🔹 Advantages:

- Fast and efficient

- High repeatability

- Cost-effective for large volumes

- Teacher: ALBERT IMANIRAFASHA

Metal Cutting is a fundamental manufacturing process in which material is removed from a metal workpiece in the form of chips to achieve a desired shape, size, and surface finish.

Key Elements of Metal Cutting:

-

Workpiece: The material being machined (usually metal).

-

Cutting Tool: A harder material used to shear off the metal.

-

Machine Tool: The device (e.g., lathe, milling machine) that provides motion between the tool and the workpiece.

- Teacher: ALBERT IMANIRAFASHA

This course provides students with both theoretical knowledge and practical skills required to perform Shielded Metal Arc Welding (SMAW) on mild steel effectively and safely in various applications. The focus is on understanding the properties of mild steel, welding tools and equipment, electrode selection, and step-by-step welding techniques.

- Teacher: ELIE NSENGIMANA

This course provides students with both theoretical knowledge and practical skills required to assemble aluminum profiles effectively and safely in various applications. The focus is on understanding the properties of aluminum profiles, required tools, connection methods, and step-by-step assembly techniques.

- Teacher: ELIE NSENGIMANA

Oxy-acetylene gas welding is a fusion welding process that uses a flame produced by burning acetylene (C₂H₂) with oxygen (O₂) to melt and join metals.

2. Equipment Used:

-

Oxygen cylinder (black)

-

Acetylene cylinder (maroon)

-

Pressure regulators

-

Hoses (red for acetylene, blue for oxygen)

-

Welding torch

-

Welding tips/nozzles

-

Spark lighter

-

Protective gear (goggles, gloves, apron)

3. Types of Flames:

-

Neutral flame (1:1 ratio of oxygen and acetylene) – used for most welding.

-

Carburizing flame (excess acetylene) – used for welding high-carbon steels and non-ferrous metals.

-

Oxidizing flame (excess oxygen) – used for brass, bronze, and certain steels.

4. Advantages:

-

Portable and versatile.

-

Low initial equipment cost.

-

Suitable for welding, cutting, brazing, and heating.

-

Ideal for thin metal sheets and maintenance work.

5. Disadvantages:

-

Not suitable for welding thick sections.

-

Slower than arc welding.

-

Generates lower temperatures.

-

Fire and explosion risks due to combustible gases.

6. Applications:

-

Sheet metal work

-

Automobile repairs

-

Plumbing and refrigeration

-

Metal sculpture and art

7. Safety Precautions:

-

Check for leaks before use.

-

Use in well-ventilated areas.

-

Never use oil or grease on regulators or fittings.

-

Keep cylinders upright and secured.

-

Follow correct lighting and shutdown procedures.

- Teacher: ALBERT IMANIRAFASHA