Enrolment options

Basics of Hydraulic System

-

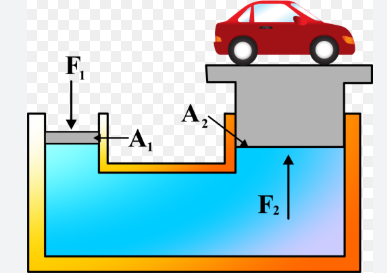

Definition: A hydraulic system is a power transmission system that uses pressurized liquid (usually oil) to transmit force and motion.

-

Principle: It works on Pascal’s Law, which states that pressure applied at one point of an enclosed fluid is transmitted equally in all directions.

-

Main Components:

-

Hydraulic pump (converts mechanical power into fluid power)

-

Valves (control pressure, flow, and direction)

-

Actuators (cylinders or motors that convert fluid power into mechanical motion)

-

Hydraulic fluid (medium for power transmission and lubrication)

-

-

Applications: Heavy machinery (excavators, presses), automotive brakes, aircraft systems.

-

Advantages: High force output, precise control, smooth operation.

Basics of Pneumatic System

-

Definition: A pneumatic system is a power transmission system that uses compressed air or gas to transmit and control energy.

-

Principle: It works on the compression and expansion of air; force is generated by pressurized air acting on a piston or actuator.

-

Main Components:

-

Compressor (supplies compressed air)

-

Valves (control air pressure, flow, and direction)

-

Actuators (pneumatic cylinders, air motors)

-

Air treatment units (filters, regulators, lubricators)

-

-

Applications: Automation in industries, packaging machines, air brakes, dental tools.

-

Advantages: Clean, lightweight, safe in hazardous environments, simple design.

- Teacher: OLIVIER MPARIBATENDA