General

Overview

Introduction

This module is part of the Mining and Manufacturing Sector in the Production and Technology subsector. It is designed for Level 3 TVET Certificate. It is a core module that describes the performance outcomes, skills, knowledge, and attitude required to perform the SMAW welding process for Mechanical fitters.

Learning Objectives

By the end of the module, trainees will be able to:

- Organize workplace

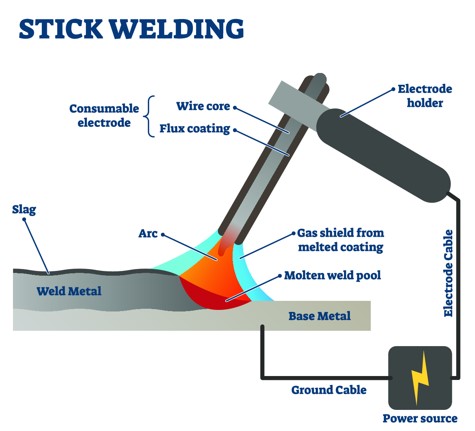

- Execute the welded joints using SMAW

- Check the work done

- Clean and store tools and equipment