Search results: 629

This specific module describes the skills, knowledge, and attitudes required to perform ornamental finishing works. It is meant for learners who have completed level IV in building construction and pursuing level V in building construction. At the end of this module, learners will be able to perform cladding installation, install glass, and apply paint coats.

- Teacher: Uwimbabazi Antoinette

The purpose of learning ornamental finishing works is to equip you with the skills, knowledge, and attitudes required to improve the beauty, protection, and value of buildings. You will learn how to apply different finishes, You will protect building surfaces from weathering and damage and You will contribute to making buildings attractive, durable, and comfortable.

- Teacher: MUKANSANGA PASCALINE

Course Summary: Ornamental Finishing Works

The course on Ornamental Finishing Works introduces learners to the principles, materials, and techniques used in enhancing the aesthetic and functional qualities of buildings through decorative finishes. It emphasizes practical skills and theoretical knowledge required to execute works such as plaster mouldings, cornices, terrazzo finishes, wall and ceiling decorations, floor finishes, and other ornamental treatments.

The module covers the identification and preparation of finishing materials, use of appropriate tools and equipment, surface preparation, and application techniques to achieve durable and visually appealing finishes. It also integrates aspects of measurement, cost estimation, safety, and quality standards in ornamental works.

By the end of the course, students will have the competence to interpret drawings and specifications, prepare work surfaces, apply decorative finishes, and maintain high standards of workmanship that align with both traditional and modern construction practices.

- Teacher: JACQUES NZAMUKWEREKA

Ornamental finishing work refers to the decorative treatments and details applied to buildings after the main structural work is complete. These finishes are not just about beauty—they also serve functional purposes like protecting surfaces, improving durability, and sometimes even enhancing insulation or fire resistance.

Oxy-acetylene gas welding is a fusion welding process that uses a flame produced by burning acetylene (C₂H₂) with oxygen (O₂) to melt and join metals.

2. Equipment Used:

-

Oxygen cylinder (black)

-

Acetylene cylinder (maroon)

-

Pressure regulators

-

Hoses (red for acetylene, blue for oxygen)

-

Welding torch

-

Welding tips/nozzles

-

Spark lighter

-

Protective gear (goggles, gloves, apron)

3. Types of Flames:

-

Neutral flame (1:1 ratio of oxygen and acetylene) – used for most welding.

-

Carburizing flame (excess acetylene) – used for welding high-carbon steels and non-ferrous metals.

-

Oxidizing flame (excess oxygen) – used for brass, bronze, and certain steels.

4. Advantages:

-

Portable and versatile.

-

Low initial equipment cost.

-

Suitable for welding, cutting, brazing, and heating.

-

Ideal for thin metal sheets and maintenance work.

5. Disadvantages:

-

Not suitable for welding thick sections.

-

Slower than arc welding.

-

Generates lower temperatures.

-

Fire and explosion risks due to combustible gases.

6. Applications:

-

Sheet metal work

-

Automobile repairs

-

Plumbing and refrigeration

-

Metal sculpture and art

7. Safety Precautions:

-

Check for leaks before use.

-

Use in well-ventilated areas.

-

Never use oil or grease on regulators or fittings.

-

Keep cylinders upright and secured.

-

Follow correct lighting and shutdown procedures.

- Teacher: ALBERT IMANIRAFASHA

Our module covers Oxy-Acetylene Gas Welding on Mild Steel, structured into three key learning outcomes. First, it focuses on preparing for welding operations by introducing the process, highlighting safety, health, and environmental practices, and identifying the necessary tools and equipment. The second part emphasizes applying welding techniques on mild steel, including interpreting technical drawings, workpiece preparation, flame ignition, welding positions, types of welds, identifying defects, and finishing work. The final part deals with post-operation activities such as maintaining equipment and proper reporting. This module ensures trainees gain practical skills for safe and effective gas welding operations.

- Teacher: |GIRINSHUTI Fabrice

Our module covers Oxy-Acetylene Gas Welding on Mild Steel, structured into three key learning outcomes. First, it focuses on preparing for welding operations by introducing the process, highlighting safety, health, and environmental practices, and identifying the necessary tools and equipment. The second part emphasizes applying welding techniques on mild steel, including interpreting technical drawings, workpiece preparation, flame ignition, welding positions, types of welds, identifying defects, and finishing work. The final part deals with post-operation activities such as maintaining equipment and proper reporting. This module ensures trainees gain practical skills for safe and effective gas welding operations.

- Teacher: |GIRINSHUTI Fabrice

Oxyacetylene welding is a gas welding process that uses a flame produced by burning acetylene in oxygen. It's typically used for joining metals, including aluminum in some cases.

Key Characteristics When Welding Aluminum:

- Melting Point: Aluminum melts at a relatively low temperature (~660°C), making it suitable for gas welding but prone to overheating.

- Oxide Layer: Aluminum forms a tough aluminum oxide layer (~2050°C melting point), which must be removed before welding. This is usually done using a stainless steel wire brush or chemical cleaning.

- Flux: A special aluminum welding flux is required to prevent oxidation during welding and help clean the joint.

Welding Process:

- Surface Preparation:

- Remove oxide layer and clean the surface thoroughly.

- Apply flux to prevent reoxidation.

- Torch Settings:

- Use a neutral flame (equal parts oxygen and acetylene).

- Avoid oxidizing flame (can degrade aluminum).

- Welding Technique:

- Use a soft, sweeping motion to avoid overheating.

- Use appropriate aluminum filler rod.

- Flux residue must be cleaned after welding to prevent corrosion.

Advantages:

- Portable and inexpensive setup.

- Suitable for thin aluminum sheets.

- No need for electricity.

Disadvantages:

- Not ideal for thick aluminum sections.

- Higher skill required due to aluminum’s heat sensitivity.

- Flux residue can cause corrosion if not cleaned properly.

- Teacher: ALBERT IMANIRAFASHA

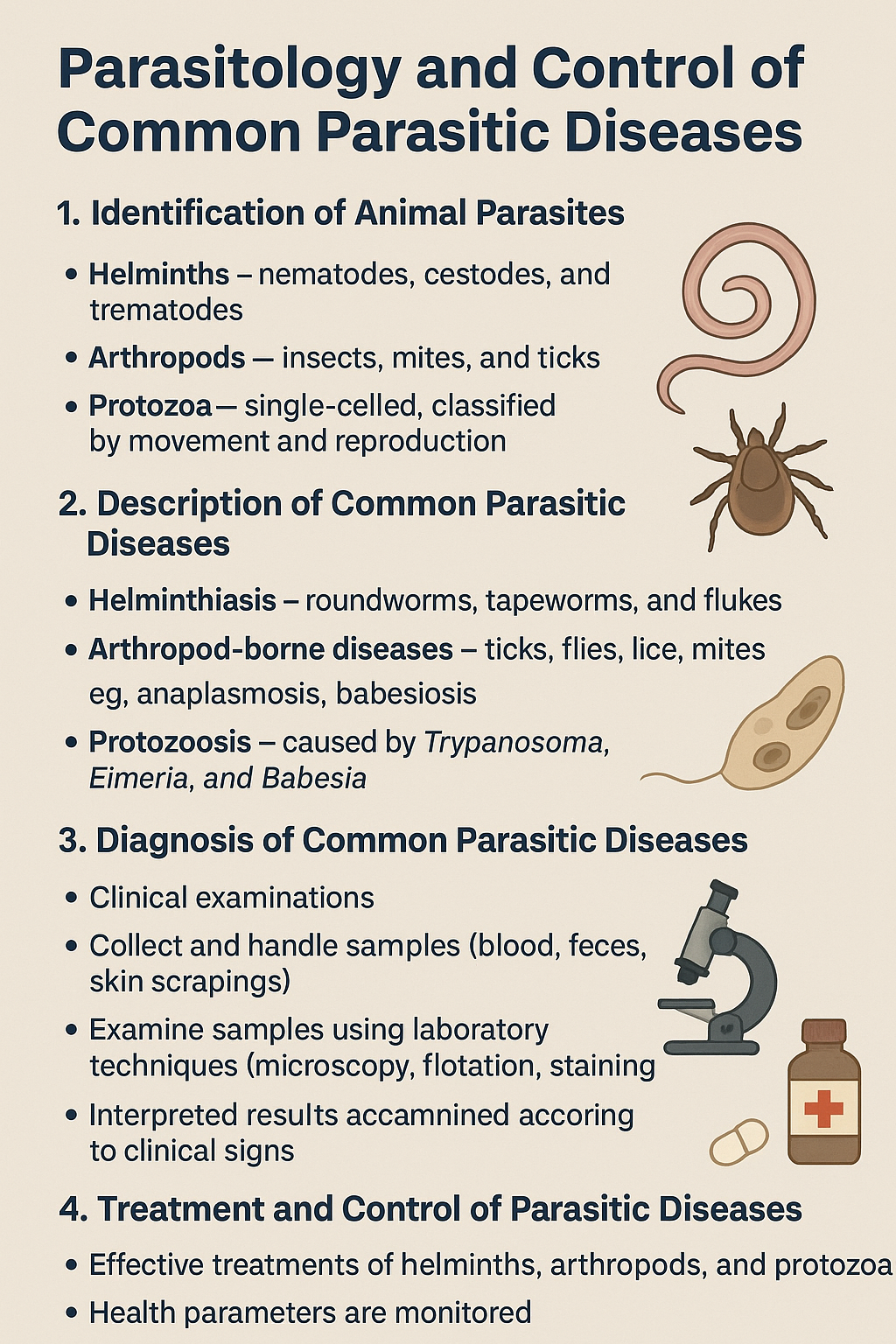

This module focuses on identifying, diagnosing, and managing animal parasites to promote animal health and productivity. It covers the major groups of parasites—helminths, arthropods, and protozoa—and their associated diseases.

1. Identification of Animal Parasites

Learners study the main classes of parasites:

-

Helminths – including nematodes, cestodes, and trematodes, described by their structure, lifecycle, and mode of infection.

-

Arthropods – such as insects, mites, and ticks, described by their morphology, development, and role as vectors.

-

Protozoa – single-celled parasites classified based on movement (flagella, cilia, pseudopodia) and mode of reproduction.

2. Description of Common Parasitic Diseases

Students learn about major parasitic diseases:

-

Helminthiasis – caused by parasitic worms like roundworms, tapeworms, and flukes.

-

Arthropod-borne diseases – caused or transmitted by ticks, flies, lice, and mites (e.g., anaplasmosis, babesiosis).

-

Protozoosis – caused by protozoan parasites such as Trypanosoma, Eimeria, and Babesia.

3. Diagnosis of Common Parasitic Diseases

The module trains students to:

-

Conduct clinical examinations following proper procedures.

-

Collect and handle samples (blood, feces, skin scrapings, etc.) according to protocols.

-

Examine samples using laboratory techniques (microscopy, flotation, staining).

-

Interpret results accurately based on clinical signs and lab findings.

4. Treatment and Control of Parasitic Diseases

Learners gain practical skills in:

-

Applying effective treatments specific to helminths, arthropods, and protozoa.

-

Monitoring animal health during and after treatment.

-

Implementing biosecurity and preventive measures such as sanitation, vector control, vaccination, and isolation to reduce disease spread.

- Teacher: NIYONZIMA Fiston

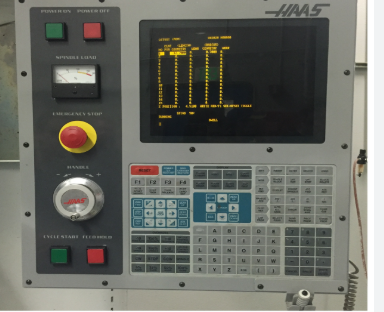

This module introduces the principles, processes, and practical techniques involved in producing mechanical parts using CNC machines. It covers both theoretical understanding and hands-on skills, enabling students or technicians to create accurate, repeatable, and high-quality component

- Teacher: ALBERT IMANIRAFASHA

- Teacher: RAISSA IRADUKUNDA

Parts production on a CNC machine is the process of creating mechanical components by using computer-controlled tools to shape raw materials into finished products. It involves the use of CAD/CAM software to design the part, generate machining codes (G-code), and guide the CNC machine in executing precise operations such as cutting, milling, turning, drilling, and grinding.

The process begins with preparing the design, selecting suitable material, and setting up the machine with the required tools. Once the program is loaded, the CNC machine automatically performs machining operations with high accuracy, speed, and repeatability, producing parts that meet the required dimensions, tolerances, and surface finish.

CNC parts production is widely used in industries like automotive, aerospace, medical, and manufacturing, where consistency and precision are essential. It allows for mass production, reduced errors, and cost efficiency compared to manual machining.

This course introduces learners to the principles and practices of producing mechanical parts using Computer Numerical Control (CNC) machines. It covers the fundamentals of CNC machining, including the structure and functions of CNC machines, interpretation of engineering drawings, selection of tools and cutting parameters, and the preparation of CNC programs (G-codes and M-codes). Learners will develop skills in setting up workpieces, executing CNC operations such as turning, milling, and drilling, and applying quality control measures to ensure accuracy and precision of produced parts. The course also emphasizes safety practices, process optimization, and troubleshooting in CNC machining to prepare students for real-world manufacturing environments.

CNC (Computer Numerical Control) machines produce parts with high precision and repeatability by using programmed instructions. The process starts with a CAD model, which is converted into a CAM program that generates G-code and M-code to control tool movements, cutting speed, feed rate, and spindle rotation. Raw material fixed on a workholding device is shaped by cutting tools layer by layer into the final part, with operations such as milling, turning, drilling, and grinding often done in one setup. This method ensures accuracy, consistency, high productivity, and reduced human error, with finished parts inspected to meet quality and tolerance standards.

- Teacher: OLIVIER MPARIBATENDA

This course, Parts Production on CNC Machine will equips the learners with knowledge and practical skills to produce precision parts using Computer Numerical Control (CNC) machines. It covers CNC principles, machine components, and setup procedures such as tool selection, fixture installation, and workpiece alignment. Learners will develop and verify CNC programs using G-code, M-code, and CAD/CAM software. Emphasis is placed on cutting parameters, milling, turning, drilling operations and safe working practices to ensure efficient and accurate part production

- Teacher: NIYITEGEKA Jean Damascene

This course provides students with both theoretical knowledge and practical skills required to perform Shielded Metal Arc Welding (SMAW) on mild steel effectively and safely in various applications. The focus is on understanding the properties of mild steel, welding tools and equipment, electrode selection, and step-by-step welding techniques.

- Teacher: ELIE NSENGIMANA

This course introduces the fundamental principles and practices of sand casting, one of the oldest and most widely used manufacturing processes for producing metal parts. Students will gain theoretical knowledge and practical skills in preparing sand molds, selecting suitable materials, pouring molten metal, and finishing cast products.

- Teacher: GASPARD HARERIMANA

Bending is a metal forming process that shapes materials by applying force, causing plastic deformation where the outer surface stretches and the inner surface compresses. It is commonly performed on sheet metals, rods, and bars using machines like press brakes and roll benders. The process depends on factors such as material type, thickness, bend radius, and applied force. Accurate results require proper bend calculations and strict safety measures. Bending is widely used in manufacturing and construction to produce parts like brackets, frames, and panels.

- Teacher: GASPARD HARERIMANA