Search results: 746

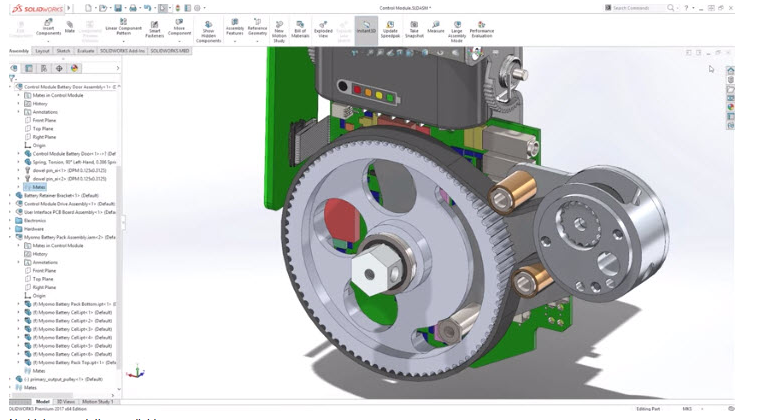

This learning outcome introduces students to SolidWorks, a 3D design software used in manufacturing and engineering. Students will learn how to open the software, understand the interface, and prepare the workspace for designing parts and assemblies

- Teacher: Illuminee BARAKAGWIRA

- Teacher: PHILIBERT GIRANEZA

- Teacher: ALBERT IMANIRAFASHA

- Teacher: RAISSA IRADUKUNDA

- Teacher: ELIE NSENGIMANA

SOLIDWORKS Design is a computer-aided design (CAD) software used to create, simulate, and visualize 2D and 3D models of products or mechanical parts. It allows engineers, designers, and manufacturers to design complex components, assemblies, and drawings with precision and efficiency. The software provides tools for sketching, modeling, rendering, and analysis, enabling users to test product performance, optimize designs, and prepare accurate technical documentation before production.

- Teacher: OLIVIER MPARIBATENDA

A SolidWorks design is a power full 3D CAD software design for mechanical parts, assemblies, and engineering drawings. It covers essentials like sketching, modeling, and drawing, plus advanced topics such as surface modeling and large assembly management. By the end, you will gain practical skills to create production-ready designs and optimize workflows in engineering and manufacturing.

- Teacher: Vedaste NDORUNKUNDIYE

- Teacher: NIYITEGEKA Patrick

This learning outcome introduces students to SolidWorks, a 3D design software used in manufacturing and engineering. Students will learn how to open the software, understand the interface, and prepare the workspace for designing parts and assemblies

- Teacher: ALBERT IMANIRAFASHA

- Teacher: Vedaste NDORUNKUNDIYE

- Teacher: Jeremie NSEKAMBABAYE

- Teacher: ELIE NSENGIMANA

- Teacher: MarieGrace UWURUKUNDO

Spot welding is a resistance welding process used to join two or more metal sheets together by applying pressure and heat generated from an electric current at small points (spots). The metal surfaces are clamped between two copper electrodes, and when current passes through, the resistance at the contact points produces enough heat to melt and fuse the metals.

It is commonly used in automotive, sheet metal, and appliance manufacturing because it is fast, clean, and efficient. However, it is mainly suitable for thin metal sheets and not ideal for thick materials or non-metallic materials.

- Teacher: NIYITEGEKA Patrick

This course provides students with both theoretical knowledge and practical skills required to perform spot welding effectively and safely in manufacturing processes. The training covers the fundamental principles of resistance spot welding, including the generation of heat through electrical resistance, material properties, and the role of electrodes. Students will learn about the types of spot welding machines, welding parameters (current, pressure, and time), and factors affecting weld quality.

- Teacher: ELIE NSENGIMANA

This module describes employable and practicable skills, knowledge and

right attitudes required by the learner to prepare the workplace for spot

welding, weld the work piece and conduct finishing activities. The content

provided in this course is package reserved for a learner pursuing TVET

certificate IV in manufacturing technology. Graduates at this level will

have knowledge and skills for spot welding and community involvement

and further leaning.

- Teacher: Pascal NDAYISHIMIYE

This

course introduces learners to the principles, techniques, and applications of spot

welding, a resistance welding process widely used in sheet metal

fabrication and automotive manufacturing. It focuses on the operation of spot

welding machines, process parameters, material considerations, and safety

measures. Learners will acquire both theoretical knowledge and practical skills

in producing quality welds, identifying defects, and applying preventive

maintenance to spot welding equipment

- Teacher: GASPARD HARERIMANA

This module encompasses all methodologies necessary to guide you to deliver the module titled: Steel bar works. Students undertaking this module shall be exposed with practical activities that will develop and nurture their competences. The writing process of this training manual embraced competency-based education and training (CBET) philosophy by providing practical opportunities reflecting real life situations.

The module is subdivided into outcomes, each unit has various indicative contents, and you will start by guiding a self-assessment exercise to help students rate themselves on their level of skills, knowledge, and attitudes about the unit.

The module will give you the information about the objectives, learning hours, didactic materials, and proposed methodologies.

This module will give you tips, methodologies, and techniques about how to facilitate students to undertake different activities as proposed in their trainee manuals. The activities in this module are prepared such that they give opportunities to students to work individually and in groups.

After going through all activities, you shall help students to undertake progressive assessments known as formative.

This module describes the knowledge, skills, and attitude to be acquired to perform reinforced steel bars works as well as performing all steps involved in making steel bars framework on the site. It is intended to be pursued by the learner at TVET level IV in building construction.

At the end of the module the learner will be able to:

1.Perform preliminary works

2.Make steel bar frames

3.Adjust steel bar frames in the formwork

4.Clean tools, equipment and the workplace

- Teacher: JeanDamascene BIMENYIMANA

- Teacher: Niyonshuti Jean Paul

- Teacher: Speratha MUKAMUHIRE

- Teacher: Wilson NIYONKURU

- Teacher: MUKANSANGA PASCALINE

- Teacher: Uwimbabazi Antoinette

- Teacher: Celestin NSABIMANA