Search results: 746

Mechanical fastening is a fundamental joining method that allows components to be assembled and disassembled without damage. This course covers common fasteners, tools, standards, and best practices for achieving strong and durable joints.

- Teacher: GASPARD HARERIMANA

Mechanical machine production is the process of creating machines and their components from raw materials. This field combines aspects of mechanical engineering, manufacturing technology, and management science to produce goods efficiently and economically.

- Teacher: NIYITEGEKA Jean Damascene

Mechanical Machine Production introduces you to core manufacturing processes used for producing mechanical machines emphasizing on advanced techniques. It covers the concept of fabrication of machine parts, assembling of machines parts and storing of machines , enabling you to produce precise and repeatable mechanical components through hands-on practice and theoretical understanding.

- Teacher: Vedaste NDORUNKUNDIYE

Metal Cutting is a fundamental manufacturing process in which material is removed from a metal workpiece in the form of chips to achieve a desired shape, size, and surface finish.

Key Elements of Metal Cutting:

-

Workpiece: The material being machined (usually metal).

-

Cutting Tool: A harder material used to shear off the metal.

-

Machine Tool: The device (e.g., lathe, milling machine) that provides motion between the tool and the workpiece.

- Teacher: ALBERT IMANIRAFASHA

This module will cover the fundamental aspects of metal cutting . It is divided into three key learning outcomes: preparing the workplace, which includes an introduction to metal cutting processes, safety practices, tool and material identification, and pre operation tasks; carrying out metal cutting, focusing on interpreting technical drawings, setting up equipment and workpieces, and performing cutting operations; and post operation activities, which involve finishing the product, cleaning the workspace and equipment, and proper storage of materials and tools. Each section includes competency development, detailed content, and end assessments to support practical skill acquisition.

- Teacher: |GIRINSHUTI Fabrice

Metal cutting is the process of removing material from a metal workpiece to give it a desired shape, size, or surface finish. This is usually done using a cutting tool that shears away small chips of metal. Metal cutting is an essential operation in manufacturing industries to create parts and components for machinery, vehicles, and equipment.

There are two main

- Teacher: OLIVIER MPARIBATENDA

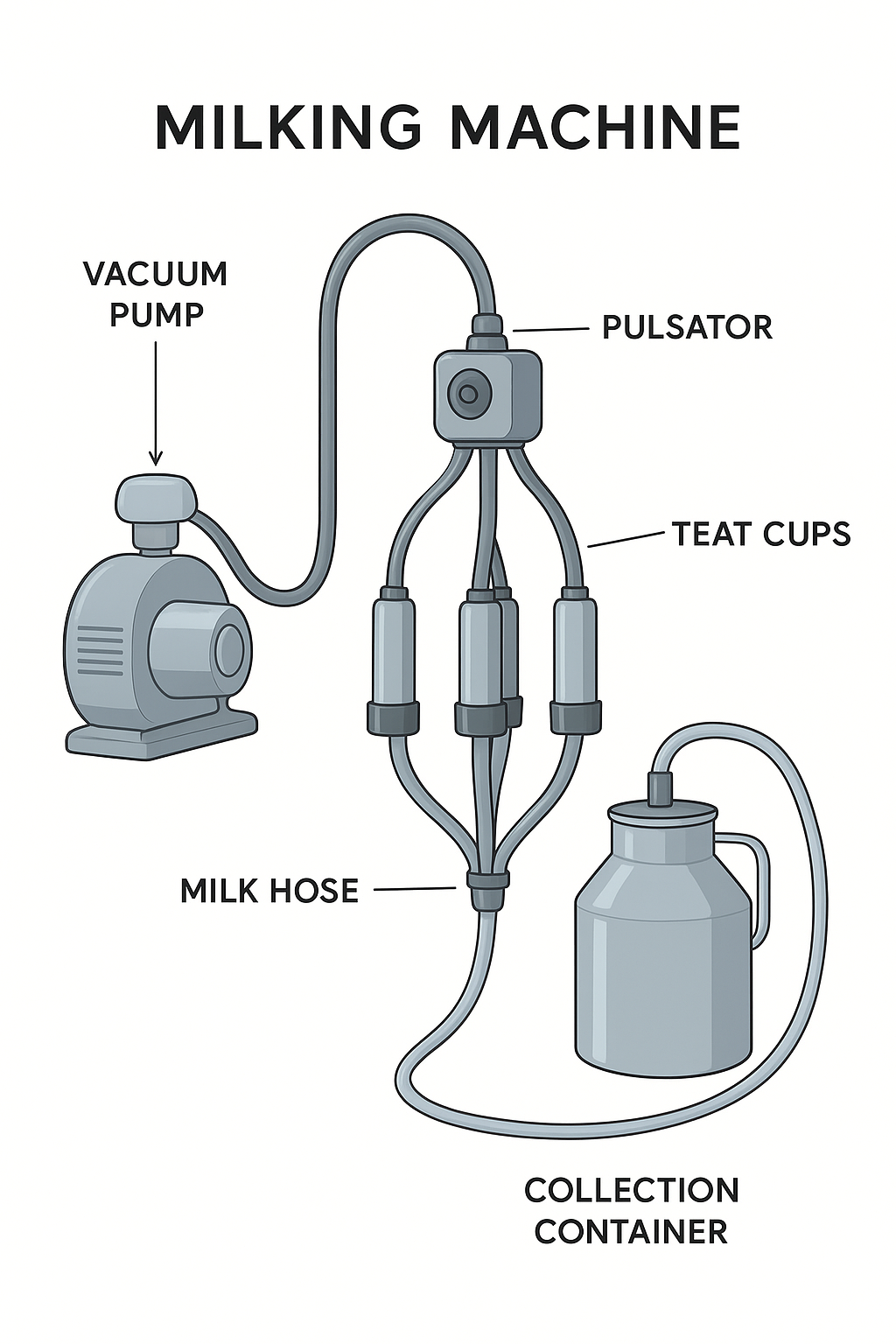

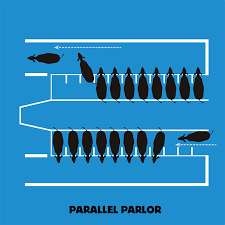

This course will describe the skills and attitudes that will help the learners from level four animal health to acquire knowledge and attitude on milking equipment hygiene , milk cows , monitoring milk quality and quantity , perform minor maintenance of troubleshooting issues and finally communicate effectively with the milking parlor team.

- Teacher: Olivier MUHOZA

- Teacher: INGABIRE Veronique

- Teacher: HAGENIMANA Eric

This module is reserved for learners of Level Five (L5) Manufacturing

Technology. It provides the skills, knowledge and attitude for learners

to be competent in Milling machine operations. After completion of this module, the learner will be able to organize the work place, set the milling machine

and mill the workpiece. She/he will be able to perform these tasks by

respecting machining quality standards and regulations requirements.

- Teacher: Pascal NDAYISHIMIYE

Milling machines are versatile machine tools used to remove material from a workpiece by feeding it against a rotating cutter. They are widely applied in manufacturing for producing flat, curved, and irregular surfaces, as well as slots, gears, and complex shapes

- Teacher: GASPARD HARERIMANA

This module is reserved for learners of Level Five (L5) Manufacturing Technology. It provides the skills, knowledge and attitude for learners to be competent in Milling machine operations. After completion of this module, the learner will be able to organize the work place, set the milling machine and mill the workpiece. She/he will be able to perform these tasks by respecting machining quality standards and regulations requirements.

- Teacher: PHILIBERT GIRANEZA

The Milling Machine Operations (MATMO501) module builds learners’ ability to organize, set up, and perform milling operations safely and efficiently. Key concepts include milling machine operation principles, workplace hazard control, product drawing interpretation, and preparation of materials, tools, and equipment. It also develops skills in setting mechanical components, adjusting milling parameters, and mounting workpieces for precision. Additionally, it emphasizes executing milling processes, inspecting and finishing milled parts, and integrating theoretical knowledge with practical application to ensure high-quality machine setup, operation, and quality assurance.

- Teacher: NIYITEGEKA Jean Damascene

Sector: ICT

Sub-sector: Computer Applications

- Teacher: Origene IGIRANEZA

This module describes the whole process of sample

analysis from field until it is analyzed in laboratory through different

activities and the use of different equipment.

- Lecturer: Eric Hitimana

- Lecturer: Origene IGIRANEZA