Search results: 215

Oxyacetylene welding is a gas welding process that uses a flame produced by burning acetylene in oxygen. It's typically used for joining metals, including aluminum in some cases.

Key Characteristics When Welding Aluminum:

- Melting Point: Aluminum melts at a relatively low temperature (~660°C), making it suitable for gas welding but prone to overheating.

- Oxide Layer: Aluminum forms a tough aluminum oxide layer (~2050°C melting point), which must be removed before welding. This is usually done using a stainless steel wire brush or chemical cleaning.

- Flux: A special aluminum welding flux is required to prevent oxidation during welding and help clean the joint.

Welding Process:

- Surface Preparation:

- Remove oxide layer and clean the surface thoroughly.

- Apply flux to prevent reoxidation.

- Torch Settings:

- Use a neutral flame (equal parts oxygen and acetylene).

- Avoid oxidizing flame (can degrade aluminum).

- Welding Technique:

- Use a soft, sweeping motion to avoid overheating.

- Use appropriate aluminum filler rod.

- Flux residue must be cleaned after welding to prevent corrosion.

Advantages:

- Portable and inexpensive setup.

- Suitable for thin aluminum sheets.

- No need for electricity.

Disadvantages:

- Not ideal for thick aluminum sections.

- Higher skill required due to aluminum’s heat sensitivity.

- Flux residue can cause corrosion if not cleaned properly.

- Teacher: ALBERT IMANIRAFASHA

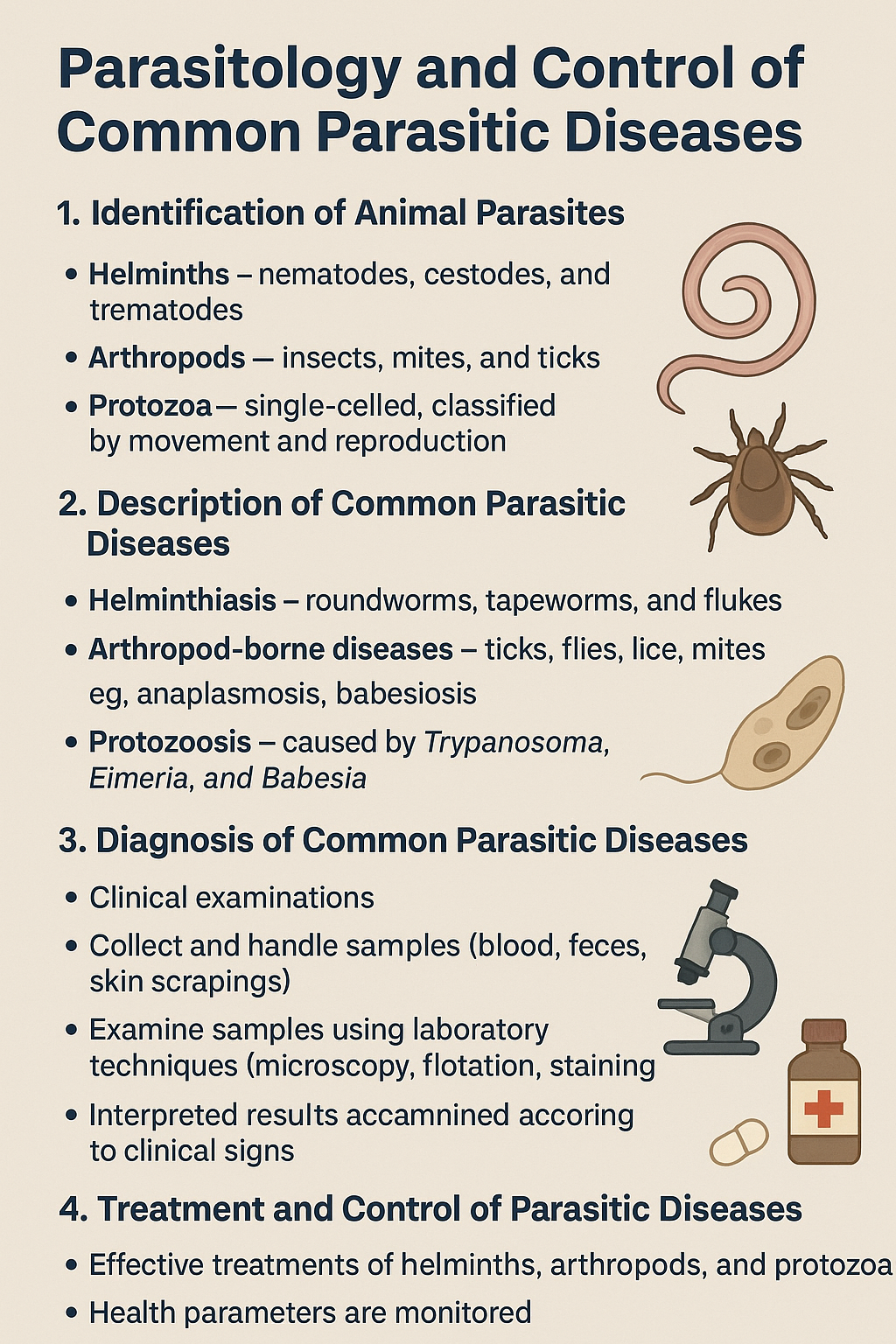

This module focuses on identifying, diagnosing, and managing animal parasites to promote animal health and productivity. It covers the major groups of parasites—helminths, arthropods, and protozoa—and their associated diseases.

1. Identification of Animal Parasites

Learners study the main classes of parasites:

-

Helminths – including nematodes, cestodes, and trematodes, described by their structure, lifecycle, and mode of infection.

-

Arthropods – such as insects, mites, and ticks, described by their morphology, development, and role as vectors.

-

Protozoa – single-celled parasites classified based on movement (flagella, cilia, pseudopodia) and mode of reproduction.

2. Description of Common Parasitic Diseases

Students learn about major parasitic diseases:

-

Helminthiasis – caused by parasitic worms like roundworms, tapeworms, and flukes.

-

Arthropod-borne diseases – caused or transmitted by ticks, flies, lice, and mites (e.g., anaplasmosis, babesiosis).

-

Protozoosis – caused by protozoan parasites such as Trypanosoma, Eimeria, and Babesia.

3. Diagnosis of Common Parasitic Diseases

The module trains students to:

-

Conduct clinical examinations following proper procedures.

-

Collect and handle samples (blood, feces, skin scrapings, etc.) according to protocols.

-

Examine samples using laboratory techniques (microscopy, flotation, staining).

-

Interpret results accurately based on clinical signs and lab findings.

4. Treatment and Control of Parasitic Diseases

Learners gain practical skills in:

-

Applying effective treatments specific to helminths, arthropods, and protozoa.

-

Monitoring animal health during and after treatment.

-

Implementing biosecurity and preventive measures such as sanitation, vector control, vaccination, and isolation to reduce disease spread.

- Teacher: NIYONZIMA Fiston

This module introduces the principles, processes, and practical techniques involved in producing mechanical parts using CNC machines. It covers both theoretical understanding and hands-on skills, enabling students or technicians to create accurate, repeatable, and high-quality component

- Teacher: ALBERT IMANIRAFASHA

- Teacher: RAISSA IRADUKUNDA

This module introduces the principles, processes, and practical

techniques involved in producing mechanical parts using CNC machines.

- Teacher: PHILIBERT GIRANEZA

- Teacher: ALBERT IMANIRAFASHA

- Teacher: RAISSA IRADUKUNDA

- Teacher: Vedaste NDORUNKUNDIYE

This course introduces learners to the principles and practices of producing mechanical parts using Computer Numerical Control (CNC) machines. It covers the fundamentals of CNC machining, including the structure and functions of CNC machines, interpretation of engineering drawings, selection of tools and cutting parameters, and the preparation of CNC programs (G-codes and M-codes). Learners will develop skills in setting up workpieces, executing CNC operations such as turning, milling, and drilling, and applying quality control measures to ensure accuracy and precision of produced parts. The course also emphasizes safety practices, process optimization, and troubleshooting in CNC machining to prepare students for real-world manufacturing environments.

This course, Parts Production on CNC Machine will equips the learners with knowledge and practical skills to produce precision parts using Computer Numerical Control (CNC) machines. It covers CNC principles, machine components, and setup procedures such as tool selection, fixture installation, and workpiece alignment. Learners will develop and verify CNC programs using G-code, M-code, and CAD/CAM software. Emphasis is placed on cutting parameters, milling, turning, drilling operations and safe working practices to ensure efficient and accurate part production

- Teacher: NIYITEGEKA Jean Damascene

This course introduces the fundamental principles and practices of sand casting, one of the oldest and most widely used manufacturing processes for producing metal parts. Students will gain theoretical knowledge and practical skills in preparing sand molds, selecting suitable materials, pouring molten metal, and finishing cast products.

- Teacher: GASPARD HARERIMANA

This course provides students with the theoretical knowledge and practical skills required to install, maintain, and troubleshoot industrial machines used in manufacturing and production environments. Learners will gain competence in reading and interpreting machine installation drawings, aligning and assembling mechanical components, connecting electrical systems, and applying appropriate maintenance procedures to ensure optimal machine performance.

The course emphasizes adherence to safety standards, preventive maintenance practices, and the use of correct tools and instruments. Students will also develop problem-solving skills for diagnosing faults and performing corrective actions to minimize downtime and extend the lifespan of industrial equipment.

- Teacher: ELIE NSENGIMANA

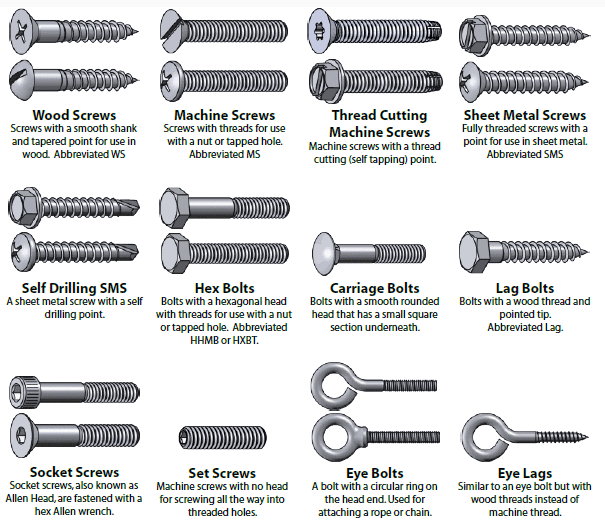

This module equips learners with the practical skills, foundational knowledge, and appropriate work attitudes required to perform mechanical fastening operations. It covers the preparation of tools, materials, and equipment; the execution of mechanical fastening tasks; and the necessary post-operation activities to ensure safety and quality.

Designed for students pursuing a TVET Certificate III in Manufacturing Technology, this module prepares graduates for entry-level roles in manufacturing, active participation in community projects, and opportunities for further learning in related technical fields.

This module describes the knowledge, skills, and attitude to be acquired in order to place

well tiles on the walls, stairs and floors. It is intended to be pursued by learner at TVET

level IV Building Construction. At the end of this module, the learner will be able to

prepare working area, select materials, tools and equipment. He/She will also be able to

cut, apply tiles, and perform grouting and cleaning of the workplace.

- Teacher: Lucie UWIZERA

This module describes knowledge, skills and attitude required in the making of decorative objects from proper preparation of tools, materials, equipment and environment. Coherent selection of items in match with the required style for an artistic composition/project that respect rules of composition

- Teacher: Origene IGIRANEZA

This

preliminary/fundamental module describes knowledge, skills and attitude

required in application of making quick drawing/sketch through a keen

observative process and proper use of art elements and principles.

- Teacher: Origene IGIRANEZA

This module is describes skills, knowledge and attitude, required to apply painting an artwork. At the end of the module the leaners will be able to prepare the working environment, paint the artworks and make the clear finishing of the artwork in respect of element and principles of painting.

- Teacher: Eric Hitimana

- Teacher: Origene IGIRANEZA

Pipes

- Purpose: Transport fluids (liquids, gases, slurries) under pressure or flow.

- Materials: Steel, copper, PVC, HDPE, etc.

- Standards: ASME B31.1 (Power piping), B31.3 (Process piping), etc.

- Components:

- Pipes

- Fittings (elbows, tees, reducers)

- Valves

- Flanges and gaskets

- Design Considerations:

- Pressure and temperature

- Flow rate

- Material compatibility

- Corrosion resistance

Pressure Vessels

- Purpose: Hold gases or liquids at a pressure substantially different from ambient pressure.

- Common Uses:

- Boilers

- Heat exchangers

- Reactors

- Storage tanks

- Materials: Carbon steel, stainless steel, composites

- Design Codes: ASME Section VIII (Boiler and Pressure Vessel Code)

- Key Parts:

- Shell

- Heads (end caps)

- Nozzles

- Supports (saddles, skirts)

- Safety Features:

- Pressure relief valves

- Burst discs

- Inspection ports

- Teacher: ALBERT IMANIRAFASHA

This module covers the knowledge, skills and attitudes required to prepare workplace for veterinary intervention. Indeed, any veterinary activity involves a proper preparation of workplace.

So, this competence is very important for the Animal care technician training, and it is a prerequisite for all the specific modules of the qualification involving the manipulation and treatment of the different animal species. It is intended for learners who have successfully completed ordinary level, level II in animal health or its equivalent and pursuing TVET level III and related qualification.

Upon completion of this module, you will be able to:

Identify and store veterinary drugs according to their therapeutic function; Identify and store veterinary instruments and equipment according to their intended use; Clean and sanitise workplace, instruments and equipment and perform proper waste disposal.

- Teacher: Rene Heritier UWURUKUNDO

This module covers the knowledge, skills and attitudes required to prevent diseases for the following species:

cow, sheep, goat, pig, poultry, rabbit, dog and cat. The workplace in which this competence may be applied

range from veterinary clinics, animal housings/shelters, farms, customs services to slaughterhouses. It’s a

prerequisite for all the specific modules of the qualification involving the manipulation and treatment of the

different species mentioned above. Upon completion of this module, the trainee will be able to: Monitor

physical conditions of animal housing; Restrain animals for veterinary intervention; Perform animal general

examination; Use antiparasitic drugs for disease prevention.

- Teacher: INGABIRE Veronique

This module, "Production of Soil-Based Bricks and Blocks," is designed to provide you with the practical knowledge and skills required to manufacture high-quality, durable, and sustainable soil-based building materials.

This module will guide you through the entire production process, from raw material selection to the final curing of the bricks. You will learn the scientific principles behind soil stabilization and compaction, and gain hands-on knowledge of the tools and techniques used in both manual and mechanized production.

- Teacher: Speratha MUKAMUHIRE

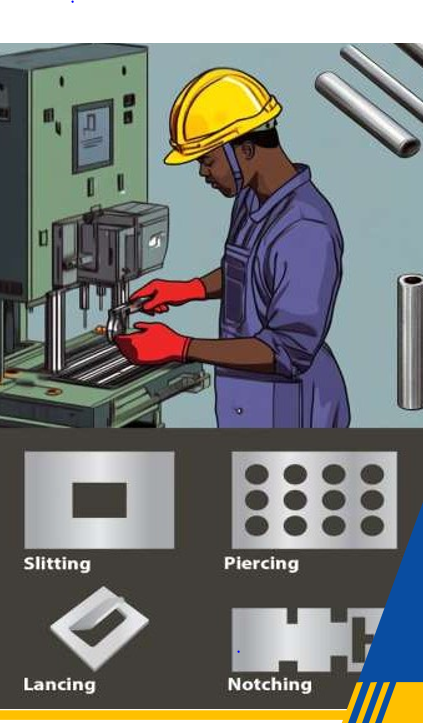

Punching operation is a type of press working process used in manufacturing where a tool (punch) is forced through sheet metal to remove a slug of material, creating a hole.

🔹 Purpose:

To create holes or cut-outs in sheet metal using a punch and die setup.

🔹 Basic Principle:

- A punch presses the sheet metal against a die.

- The punch shears the material and removes a portion (called a slug).

- The remaining material has a clean hole or profile.

🔹 Key Components:

- Punch – the tool that moves downward to cut the material.

- Die – supports the material and defines the shape of the hole.

- Sheet metal – the workpiece.

🔹 Types of Punching Operations:

- Blanking – the cut-out piece is the desired part.

- Piercing – the hole is the desired feature.

- Nibbling – series of small punches to make complex shapes.

- Perforating – punching multiple holes.

🔹 Applications:

- Automotive panels

- Electronic enclosures

- Metal brackets

- Kitchen appliances

🔹 Advantages:

- Fast and efficient

- High repeatability

- Cost-effective for large volumes

- Teacher: ALBERT IMANIRAFASHA

Punching is a metal cutting process used to create holes or shapes in a sheet of metal by using a punch and die. The punch presses the material into the die with high force, causing the sheared portion (slug) to separate from the sheet.

It is a fast and precise process commonly used in sheet metal fabrication to make holes, slots, or other cutouts for manufacturing parts. Punching offers high production speed, accuracy, and low cost for large-scale production.

- Teacher: NIYITEGEKA Patrick

This module introduces learners to the

principles and practices of software quality assurance, focusing on developing

the skills needed to ensure that applications meet user requirements and

function as expected.