Search results: 629

Machine Preventive Maintenance is a proactive approach focused on

ensuring that machines and equipment remain in optimal working condition. It

involves regularly scheduled activities intended to prevent equipment failures

and maintain operational efficiency.

- Teacher: JeanDamascene BIMENYIMANA

- Teacher: |GIRINSHUTI Fabrice

- Teacher: OLIVIER MPARIBATENDA

- Teacher: Paulin NIYIGABA

- Teacher: Wilson NIYONKURU

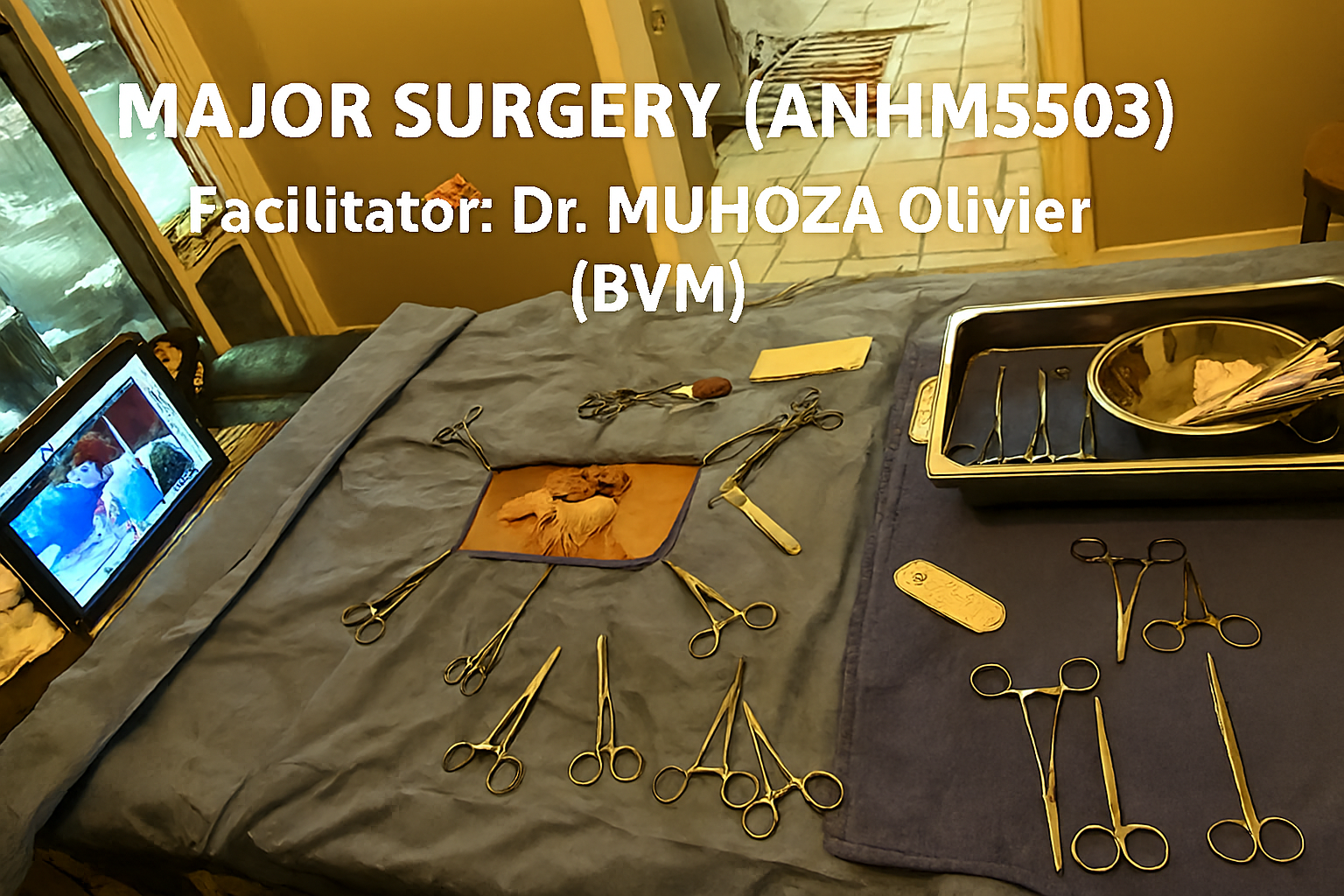

This module describes the skills, knowledge and attitude required to assist in

Major surgery. It is intended to the learners pursuing TVET Certificate V in

Animal health. Upon completion of this module the learner will be able to

perform preoperative activities, assist in surgical operations, perform post-operative care activities under minimum supervision. The module aims to provide you the required knowledge and skills that will help you to assist to surgical operations.

In this module the pre-operative activities prior to Major surgery procedures will be described. An emphasize will be made on the surgical operations to be performed following a regional body approach and the post-operative activities will lead you to the conclusion of the module. Welcome to the module.

- Teacher: Olivier MUHOZA

Purpose statement: This module describes the skills, knowledge and attitude required to assist in Major surgery. It is intended to the learners pursuing TVET Certificate V in Animal health. Upon completion of this module the learner will be able to perform preoperative activities, assist in surgical operations, perform post-operative care activities under minimum supervision.

- Teacher: JeandeDieu KUBWIMANA

At the end of this module, learners will be able to manage construction site documents, Conduct the management of construction activities, Prepare and manage contract with minimum

supervision

- Teacher: Pierre MUNYAMBONERA,

This module describes the skills, knowledge and attitudes required to set out structures,

construct stones and bricks according to standard, laying pavers and pitches according to

the standard. It is intended for learners who have successfully completed ordinary level

and pursuing level III in public works. At the end of this module, learners will be able to

clean the site, to set levelling instrument, to set structures, to construct stones and

bricks, to lay pavers and pitches.

The aim of this module is to equip learners with practical and theoretical skills required to:

- Select, maintain, and use masonry tools, equipment, and materials.

- Prepare the working area safely and efficiently.

- Prepare mortar with correct proportions.

- Erect brick and block walls to required standards.

- Apply jointing and pointing techniques to ensure durability and aesthetics.

Site Conditions means the physical and other conditions at the Site and the surrounding area as a whole, including conditions relating to the environment, transportation, access, waste disposal, handling and storage of materials, the availability and quality of electric power, the availability and quality of water, the availability and quality of roads, the availability and quality of labor personnel and local work and labor rules, climatic conditions and seasons, topography, air and water (including raw water) quality conditions, ground surface conditions, surface soil conditions, sound attenuation, subsurface geology, nature and quantity of surface and subsurface materials to be encountered (including Hazardous Materials), the geological and subsurface conditions of the Site, all other local and other conditions which may be material to Contractor’s performance of its obligations under the Agreement, and the location of underground utilities, obstructions and equipment and facilities needed before and during performance of Contractor’s obligations under the Agreement.

This module equips learners with the practical skills, technical knowledge, and positive attitudes needed to carry out oxy-acetylene gas welding operations. It focuses on applying oxy-acetylene welding to mild steel and performing essential post-welding activities. The course content is designed for students pursuing a TVET Certificate III in Manufacturing Technology. At this level, graduates gain the competencies required for entry-level employment, active participation in community projects, and progression to higher learning.

This module describes employable and practicable skills, knowledge and right attitudes required by a learner to prepare tools, materials and equipment for mechanical fastening, Carry out mechanical fastening and Perform post-operation activities. The content provided in this course are package reserved for a learner pursuing TVET certificate III in manufacturing technology. Graduates at this level will have knowledge and skills for initial work, community involvement and/or further learning.

- Teacher: RAISSA IRADUKUNDA

This Mechanical Fastening (MATMF301) provides learners with the knowledge and practical skills to join mechanical components using fasteners such as bolts, screws, nuts, and rivets. It covers preparation, including understanding fastener types, materials, tools, and pre-operation checks; execution, such as interpreting drawings, preparing parts, and applying fasteners accurately; and post-operation activities, including finishing assemblies, storing tools, and reporting work done.

- Teacher: NIYITEGEKA Jean Damascene

- Teacher: Pascal NDAYISHIMIYE

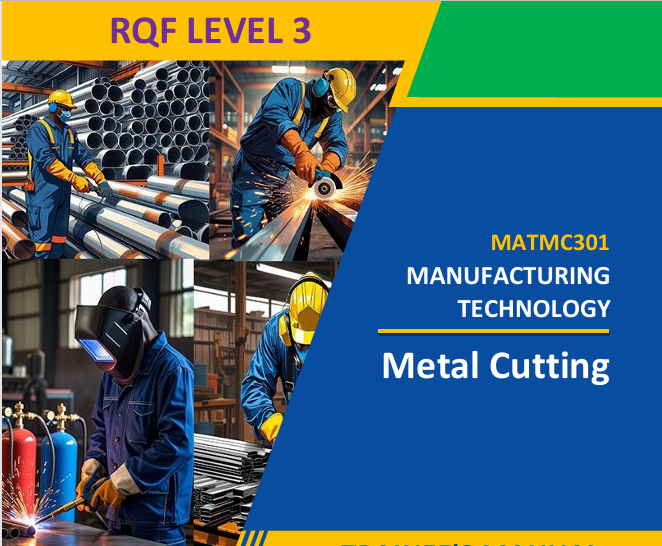

Metal Cutting is a fundamental manufacturing process in which material is removed from a metal workpiece in the form of chips to achieve a desired shape, size, and surface finish.

Key Elements of Metal Cutting:

-

Workpiece: The material being machined (usually metal).

-

Cutting Tool: A harder material used to shear off the metal.

-

Machine Tool: The device (e.g., lathe, milling machine) that provides motion between the tool and the workpiece.

- Teacher: ALBERT IMANIRAFASHA

This module will cover the fundamental aspects of metal cutting . It is divided into three key learning outcomes: preparing the workplace, which includes an introduction to metal cutting processes, safety practices, tool and material identification, and pre operation tasks; carrying out metal cutting, focusing on interpreting technical drawings, setting up equipment and workpieces, and performing cutting operations; and post operation activities, which involve finishing the product, cleaning the workspace and equipment, and proper storage of materials and tools. Each section includes competency development, detailed content, and end assessments to support practical skill acquisition.

- Teacher: |GIRINSHUTI Fabrice

Metal cutting is the process of removing material from a metal workpiece to give it a desired shape, size, or surface finish. This is usually done using a cutting tool that shears away small chips of metal. Metal cutting is an essential operation in manufacturing industries to create parts and components for machinery, vehicles, and equipment.

There are two main

- Teacher: OLIVIER MPARIBATENDA

- Teacher: Basamiraho Emmanuel

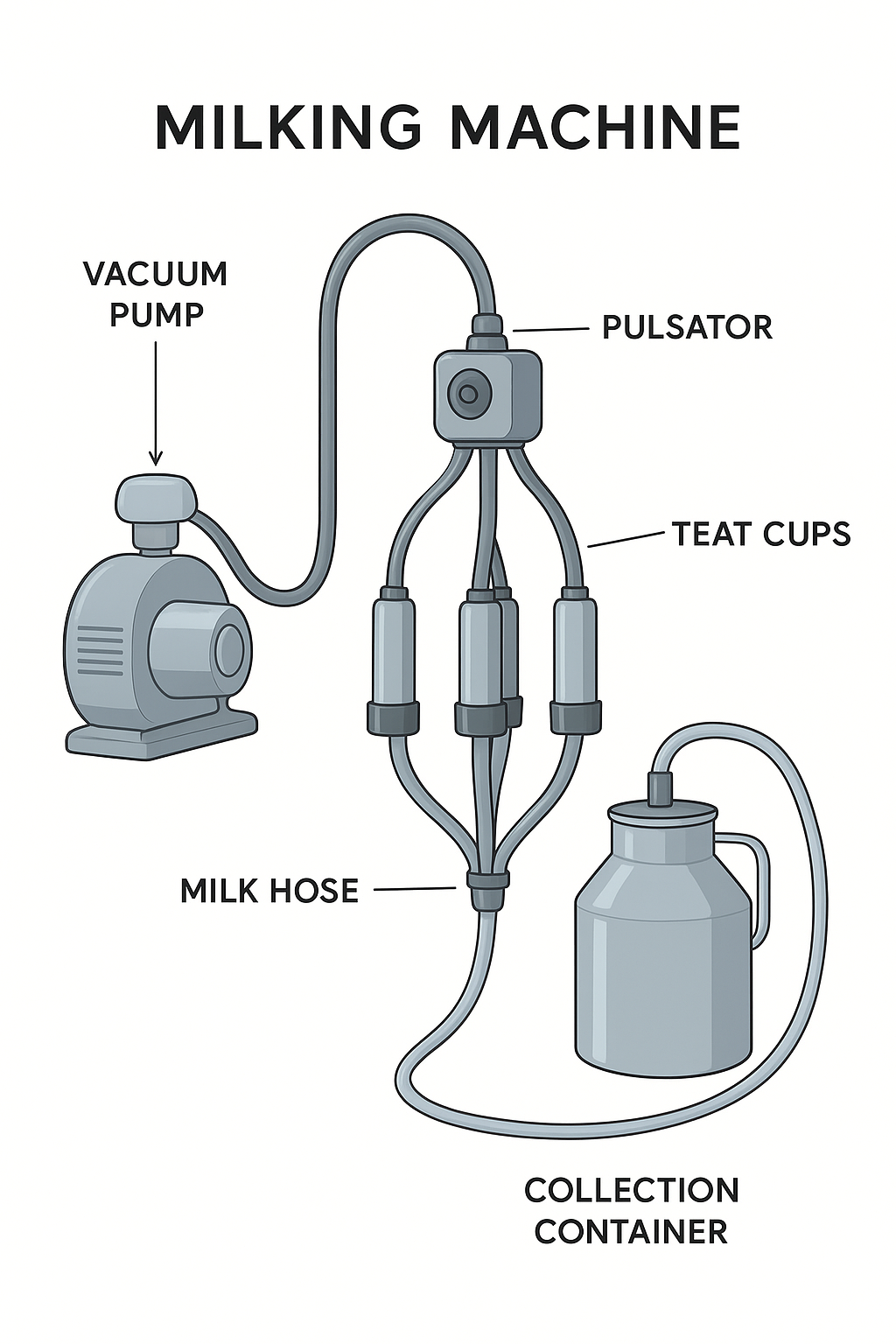

This course will describe the skills and attitudes that will help the learners from level four animal health to acquire knowledge and attitude on milking equipment hygiene , milk cows , monitoring milk quality and quantity , perform minor maintenance of troubleshooting issues and finally communicate effectively with the milking parlor team.

- Teacher: Olivier MUHOZA

- Teacher: INGABIRE Veronique