Search results: 746

Bending is a metal forming process that shapes materials by applying force, causing plastic deformation where the outer surface stretches and the inner surface compresses. It is commonly performed on sheet metals, rods, and bars using machines like press brakes and roll benders. The process depends on factors such as material type, thickness, bend radius, and applied force. Accurate results require proper bend calculations and strict safety measures. Bending is widely used in manufacturing and construction to produce parts like brackets, frames, and panels.

- Teacher: GASPARD HARERIMANA

Cement flooring, also known as concrete flooring, is one of the oldest and most widely used types of flooring in construction due to its durability, affordability, and ease of maintenance. It involves the use of a mixture of cement, sand, and water, sometimes combined with aggregates, which is poured and leveled to create a solid surface.

- Teacher: Clemence MUKASHYAKA

This course provides students with the theoretical knowledge and practical skills required to install, maintain, and troubleshoot industrial machines used in manufacturing and production environments. Learners will gain competence in reading and interpreting machine installation drawings, aligning and assembling mechanical components, connecting electrical systems, and applying appropriate maintenance procedures to ensure optimal machine performance.

The course emphasizes adherence to safety standards, preventive maintenance practices, and the use of correct tools and instruments. Students will also develop problem-solving skills for diagnosing faults and performing corrective actions to minimize downtime and extend the lifespan of industrial equipment.

- Teacher: ELIE NSENGIMANA

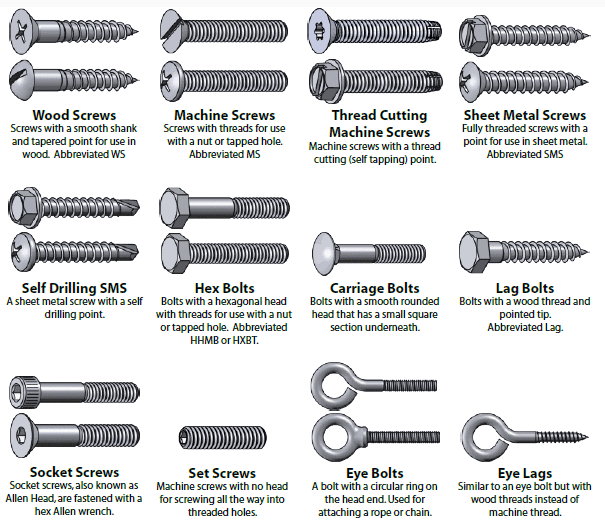

This module equips learners with the practical skills, foundational knowledge, and appropriate work attitudes required to perform mechanical fastening operations. It covers the preparation of tools, materials, and equipment; the execution of mechanical fastening tasks; and the necessary post-operation activities to ensure safety and quality.

Designed for students pursuing a TVET Certificate III in Manufacturing Technology, this module prepares graduates for entry-level roles in manufacturing, active participation in community projects, and opportunities for further learning in related technical fields.

This is a core module which describes the performance

outcomes, skills, knowledge and attitudes required, where the learner will be

able to use tools and equipment for opening fixation. The learner will be able

to fix doors, windows, ventilators and fixtures reserved for Lighting, access

and security according to the standards

- Teacher: Jean Marie Vianney TWIZEYIMANA

Course Summary: Opening Fixation

The Opening Fixation course introduces learners to the skills and knowledge required for preparing, installing, and finishing different types of building openings. These include doors, windows, ventilators, and frames that allow access, lighting, and ventilation in structures.

The course emphasizes the proper selection and handling of materials such as timber, metal, aluminum, glass, and PVC, as well as the use of appropriate tools and fasteners. Learners are trained in setting out openings, fixing frames, aligning and leveling components, and applying finishing techniques to ensure durability, functionality, and aesthetic quality.

Safety practices and quality standards are integrated throughout the training, enabling learners to perform tasks with accuracy while minimizing errors and hazards.

Upon completion, learners will be able to interpret drawings, prepare openings, and competently fix frames and shutters for doors and windows in compliance with building requirements. The course prepares learners for entry-level opportunities in carpentry, joinery, and general construction works.

- Teacher: JACQUES NZAMUKWEREKA

This specific module describes the skills, knowledge, and attitudes required to perform

ornamental finishing works. It is meant for learners who have completed level IV in

building construction and pursuing level V in building construction. At the end of this

module, learners will be able to perform cladding installation, install glass, and apply

paint coats.

- Teacher: Lucie UWIZERA

This is a core module which describes the skills, knowledge and attitude to be acquired by the learner to perform good work by preparing the working area and applying different coats in plastering in order to provide protection and good appearance of the wall at construction site and remove defects which may appear on the plastered walls. The learner deemed competent to this module may work at construction site in finishing stages under minimum supervision.

- Teacher: Jean Damascene TUYAMBAZE

Plastering is a vital process in building construction that involves covering rough surfaces of walls, ceilings, and other structural elements with a smooth layer of plaster. The main purpose of plastering is to create an even, durable, and visually appealing surface that can be painted or decorated.

- Teacher: Clemence MUKASHYAKA

Terrazzo is a composite material that originated in Italy during the 15th century.

It typically consists of chips of marble, quartz, granite, or glass mixed with a cement or epoxy binder.

The word “terrazzo” comes from the Italian word for terrace, as the original technique was used to create durable and decorative flooring in outdoor spaces.

- Teacher: Clemence MUKASHYAKA

This module describes the knowledge, skills, and attitude to be acquired in order to place

well tiles on the walls, stairs and floors. It is intended to be pursued by learner at TVET

level IV Building Construction. At the end of this module, the learner will be able to

prepare working area, select materials, tools and equipment. He/She will also be able to

cut, apply tiles, and perform grouting and cleaning of the workplace.

- Teacher: Lucie UWIZERA

- Teacher: Dieudonne TWIRINGIYIMANA