Search results: 152

Preventive Maintenance (PM) Level 4 is the most advanced and comprehensive stage in a multi-tiered PM program used in manufacturing technology. This level focuses on deep inspections, diagnostics, and overhauls to ensure long-term equipment reliability and performance. It often involves specialized personnel, advanced tools, and predictive technologies.

- Teacher: AUGUSTIN MBONIGABA

Purpose statement

This is a core module which describes the skills, knowledge and attitudes to be acquired

by the learner to produce good soil- based bricks/blocks. The learner should prepare the

materials, making good mix, molding and burn soil-based brick /blocks in order to

produce bricks or blocks of good quality. The learner deemed competent to this module

may work in construction materials production under minimum supervision.

- Teacher: Jean Damascene TUYAMBAZE

Purpose statement

Purpose statement

This module describes the knowledge, skills and attitude of quantifying various

construction works and reporting the work done. It is intended to be pursued by the

learners at TVET Certificate IV in building construction. At the end of this module, the

learner will be able to: Interpret construction drawings, determine required resources in

the construction sites, perform site data collection and reporting.

- Teacher: Jean Damascene TUYAMBAZE

This module focuses on the essential skills needed to measure and estimate all aspects of a building project accurately. The goal is to equip you with the knowledge to create a clear and realistic plan before any construction begins.

Here are the key topics we would explore:

Understanding a Bill of Quantities (BoQ): We'll learn how a BoQ serves as the blueprint for a project's costs and materials. It's the document that lists every item needed for the construction.

Material Estimation (Takeoffs): This section would teach you the methods for calculating the exact quantities of materials required, from the number of bricks to the amount of mortar and concrete.

Labor and Costing: You'd learn how to estimate the labor hours and skills needed for each task, and then how to translate all of these figures into an accurate total project cost.

Reporting and Documentation: Finally, we'd cover the importance of keeping detailed records and reports for project management and financial tracking.

In essence, this module is about ensuring that your project is not only well-built but also well-planned and financially sound.

- Teacher: Speratha MUKAMUHIRE

Course Summary: Quantifying Construction Works

Quantifying Construction Works is a course designed to equip learners with the knowledge and skills necessary to measure, estimate, and value construction activities. The course focuses on the principles and techniques of taking-off quantities from drawings, preparing bills of quantities, and applying standard methods of measurement. Students will develop competencies in interpreting construction drawings, identifying work items, and performing accurate calculations for materials, labor, and costs.

The course also emphasizes the importance of accuracy, consistency, and adherence to industry standards in quantity surveying practice. It prepares learners for effective participation in cost estimation, project planning, and tendering processes in the construction industry.

By the end of the course, learners will be able to:

-

Apply standard measurement methods in quantifying construction works.

-

Take off quantities for various building and civil engineering works.

-

Prepare bills of quantities and schedules of materials.

-

Assist in cost estimation, budgeting, and tender documentation.

-

Contribute to efficient resource management in construction projects.

- Teacher: JACQUES NZAMUKWEREKA

Course Summary: Reinforcement Steel Bars Works

This course introduces learners to the principles, techniques, and practices of working with reinforcement steel bars (rebar) used in reinforced concrete construction. It covers the identification, selection, cutting, bending, placing, and tying of reinforcement steel according to construction drawings and specifications. Emphasis is placed on ensuring structural strength, durability, and safety of reinforced concrete elements such as beams, slabs, columns, and foundations.

The module also highlights standard codes of practice, tools and equipment for reinforcement work, safety measures, and quality control in reinforcement placement. Learners gain both theoretical knowledge and hands-on skills required in the preparation and installation of reinforcement steel in building and civil engineering projects.

By the end of this course, learners will be able to:

-

Understand the role of reinforcement steel in concrete structures.

-

Identify types, grades, and sizes of reinforcement bars.

-

Interpret reinforcement detailing from construction drawings.

-

Cut, bend, and tie reinforcement bars to required shapes and dimensions.

-

Place and secure reinforcement in formwork according to standards.

-

Apply safety and quality control measures during reinforcement works.

- Teacher: JACQUES NZAMUKWEREKA

This module describe as a metal forming process in which a piece of metal is passed through one or more pairs of rotating rolls to reduce its thickness, make it uniform, and/or give it a desired cross-sectional shape

- Teacher: OLIVIER MPARIBATENDA

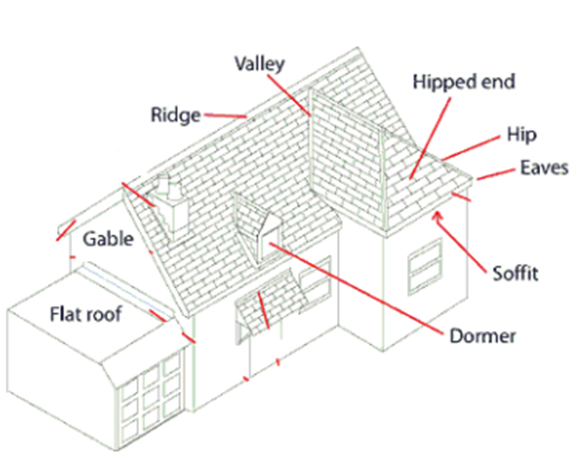

At the end of this module every learner should be to construct roof and to make roof covering.

- Teacher: Silas MAJYAMBERE

Constructing a roof structure is a critical phase in building construction that provides protection, stability, and architectural character to a structure. A well-designed roof not only shields the interior from environmental elements like rain, wind, and sunlight, but also contributes to the overall durability and energy efficiency of the building. Roof construction involves careful planning, selection of appropriate materials, and adherence to structural design principles to ensure safety and functionality. Depending on the design and purpose of the building, roofs can vary in shape and complexity—from simple flat roofs to intricate pitched or gabled forms. Key components such as trusses, rafters, beams, and decking must be precisely assembled to support the roof covering and distribute loads evenly. Successful roof construction requires coordination between architects, engineers, and builders, ensuring the structure meets both aesthetic and structural standards.

- Teacher: JEANDAMASCENE NIYIBIZI

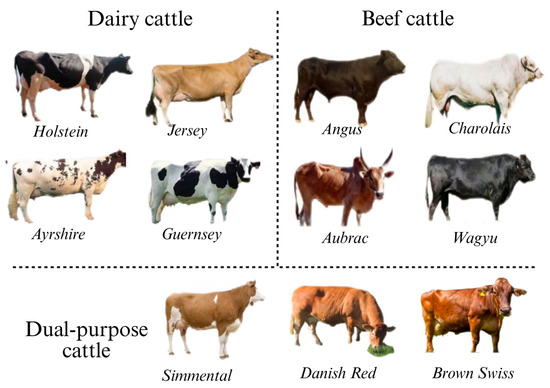

Ruminants are essential to livestock farming, especially in regions like Rwanda where they contribute significantly to food security, income generation, and sustainable agriculture. Each breed of cattle, goat, and sheep has unique characteristics that determine its suitability for meat, milk, fiber, or labor production. Identifying these breeds accurately is the first step toward effective farm management and breeding programs.

- Teacher: Basamiraho Emmanuel

- Teacher: JeandeDieu KUBWIMANA

- Teacher: Patrick NGABONZIZA

This course offers a complete guide to ruminant farming, broken down into five key learning outcomes.

It begins with Learning outcome 1, which focuses on the proper identification of common cattle, goat, and sheep breeds, detailing their unique physical and genetic characteristics.

Learning outcome 2 moves into practical farm management, covering the essential criteria for selecting a suitable site for ruminant shelters and identifying the appropriate construction materials and equipment needed for efficient operations.

Learning outcome 3 explains how to design shelters based on different production systems, from traditional to commercial.

The course then addresses animal health and productivity in Learning outcome 4, which outlines proper reproduction management, including breeding techniques, parturition assistance, and milk and weaning management.

Finally, Learning outcome 5 covers the nutritional needs of ruminants, providing guidance on feeding based on farming systems and managing common deficiencies to ensure animal health and optimal production.

- Teacher: ALEXIE MUMUKUNDE

Course Summary: Scaffolding Operations

The Scaffolding Operations course equips learners with the knowledge, skills, and attitudes required to safely plan, erect, use, inspect, and dismantle scaffolding structures at construction sites. The course emphasizes compliance with safety regulations, proper selection of materials, risk assessment, and teamwork in scaffolding tasks.

Learners will be introduced to different types of scaffolds, their components, and methods of assembly and disassembly. Special attention is given to accident prevention, load management, hazard identification, and safe working practices when working at heights. Practical sessions allow learners to gain hands-on experience in using scaffolding tools, equipment, and protective gear.

By the end of the course, participants will be able to:

-

Interpret scaffolding drawings and specifications.

-

Select appropriate materials, tools, and equipment for scaffolding tasks.

-

Safely erect, maintain, and dismantle scaffolding structures.

-

Conduct routine checks and inspections for stability and safety.

-

Apply occupational health and safety measures in scaffolding operations.

This course is designed for construction workers, site supervisors, and trainees who aim to build competence in scaffolding as part of broader construction operations.

- Teacher: JACQUES NZAMUKWEREKA

1. SMAW on Aluminum

-

Overview: Lightweight, highly conductive; difficult to weld due to oxide layer.

-

Electrodes: 4043, 5356 (AC).

-

Key Points: AC current needed, preheat thick sections, avoid excessive heat to prevent burn-through.

-

Applications: Repairs and maintenance when TIG is not available.

2. SMAW on Stainless Steel

-

Overview: Corrosion-resistant, retains high-temperature strength.

-

Electrodes: 308L, 309L, 316L.

-

Key Points: Low heat input, clean surfaces, multi-pass for thick sections.

-

Applications: Chemical, food processing, and construction industries.

3. SMAW on Cast Iron

-

Overview: Brittle, high carbon; prone to cracking.

-

Electrodes: Nickel-based (ENi-CI, ENiFe-CI).

-

Key Points: Preheat 300–600°C, slow cooling, mostly for repair work.

-

Applications: Repairing machinery, engine blocks, pipes

- Teacher: OLIVIER MPARIBATENDA

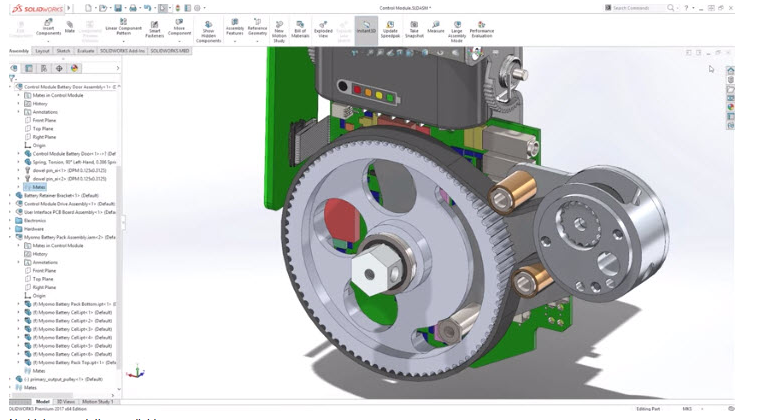

This learning outcome introduces students to SolidWorks, a 3D design software used in manufacturing and engineering. Students will learn how to open the software, understand the interface, and prepare the workspace for designing parts and assemblies

- Teacher: Illuminee BARAKAGWIRA

- Teacher: PHILIBERT GIRANEZA

- Teacher: ALBERT IMANIRAFASHA

- Teacher: RAISSA IRADUKUNDA

- Teacher: ELIE NSENGIMANA

A SolidWorks design is a power full 3D CAD software design for mechanical parts, assemblies, and engineering drawings. It covers essentials like sketching, modeling, and drawing, plus advanced topics such as surface modeling and large assembly management. By the end, you will gain practical skills to create production-ready designs and optimize workflows in engineering and manufacturing.

- Teacher: Vedaste NDORUNKUNDIYE

- Teacher: NIYITEGEKA Patrick

SOLIDWORKS Design is a computer-aided design (CAD) software used to create, simulate, and visualize 2D and 3D models of products or mechanical parts. It allows engineers, designers, and manufacturers to design complex components, assemblies, and drawings with precision and efficiency. The software provides tools for sketching, modeling, rendering, and analysis, enabling users to test product performance, optimize designs, and prepare accurate technical documentation before production.

- Teacher: OLIVIER MPARIBATENDA

This learning outcome introduces students to SolidWorks, a 3D design software used in manufacturing and engineering. Students will learn how to open the software, understand the interface, and prepare the workspace for designing parts and assemblies

- Teacher: ALBERT IMANIRAFASHA

- Teacher: Vedaste NDORUNKUNDIYE

- Teacher: Jeremie NSEKAMBABAYE

- Teacher: ELIE NSENGIMANA

- Teacher: MarieGrace UWURUKUNDO

This module encompasses all methodologies necessary to guide you to deliver the module titled: Steel bar works. Students undertaking this module shall be exposed with practical activities that will develop and nurture their competences. The writing process of this training manual embraced competency-based education and training (CBET) philosophy by providing practical opportunities reflecting real life situations.

The module is subdivided into outcomes, each unit has various indicative contents, and you will start by guiding a self-assessment exercise to help students rate themselves on their level of skills, knowledge, and attitudes about the unit.

The module will give you the information about the objectives, learning hours, didactic materials, and proposed methodologies.

This module will give you tips, methodologies, and techniques about how to facilitate students to undertake different activities as proposed in their trainee manuals. The activities in this module are prepared such that they give opportunities to students to work individually and in groups.

After going through all activities, you shall help students to undertake progressive assessments known as formative.