In this module of MATSW 301: SMAW on Mild Steel, we will develop the skills and knowledge required to perform Shielded Metal Arc Welding (SMAW) on mild steel in a safe, accurate, and efficient manner. The module is divided into three main learning outcomes: preparing for SMAW operations, applying SMAW techniques on mild steel, and carrying out post-operation activities. Trainees will learn how to identify and follow safety procedures, select appropriate tools and materials, interpret technical drawings, set up and operate welding equipment, inspect welds, and properly clean and store equipment. This competency-based training is designed to meet TVET standards and prepare learners for real-world welding tasks.

Search results: 629

This module equips learners with the essential knowledge, practical skills, and professional attitudes required to perform core operations in ruminant farming. It is designed for students pursuing Level 3 in Animal Health or related fields.

- Teacher: SadakoSandrine UMUKUNZI

This module is aimed to improve basic skills on accessing highest leeeeeeeeeeeeeeeeeeee

This

specific module describes the skills, knowledge, and attitudes required to

erect scaffolding. It is meant for learners who have successfully completed

level IV in building construction and pursuing level V in building

construction. At the end of this module, learners will be able to perform

preliminary works, assemble the scaffolding units, Monitor use of scaffolding

and dismantle the scaffolding units.

- Teacher: Vestine MUNKURIZE

Course Summary: Scaffolding Operations

The Scaffolding Operations course equips learners with the knowledge, skills, and attitudes required to safely plan, erect, use, inspect, and dismantle scaffolding structures at construction sites. The course emphasizes compliance with safety regulations, proper selection of materials, risk assessment, and teamwork in scaffolding tasks.

Learners will be introduced to different types of scaffolds, their components, and methods of assembly and disassembly. Special attention is given to accident prevention, load management, hazard identification, and safe working practices when working at heights. Practical sessions allow learners to gain hands-on experience in using scaffolding tools, equipment, and protective gear.

By the end of the course, participants will be able to:

-

Interpret scaffolding drawings and specifications.

-

Select appropriate materials, tools, and equipment for scaffolding tasks.

-

Safely erect, maintain, and dismantle scaffolding structures.

-

Conduct routine checks and inspections for stability and safety.

-

Apply occupational health and safety measures in scaffolding operations.

This course is designed for construction workers, site supervisors, and trainees who aim to build competence in scaffolding as part of broader construction operations.

- Teacher: JACQUES NZAMUKWEREKA

This specific module describes the skills, knowledge, and attitudes required to erect

scaffolding. It is meant for learners who have successfully completed level IV in building

construction and pursuing level V in building construction.

- Teacher: Celestin NDAYAMBAJE

This specific module describes the skills, knowledge, and attitudes required to erect

scaffolding. It is meant for learners who have successfully completed level IV in building

construction and pursuing level V in building construction. At the end of this module,

learners will be able to perform preliminary works, assemble the scaffolding units,

Monitor use of scaffolding and dismantle the scaffolding units.

- Teacher: Jean Marie Vianney TWIZEYIMANA

This course equips students with the knowledge and practical skills required to perform Shielded Metal Arc Welding (SMAW) on aluminium, stainless steel, and cast iron materials. It introduces the properties and challenges of welding these metals, electrode selection, preparation techniques, and the effects of heat input on weld quality

- Teacher: ELIE NSENGIMANA

SMAW on mild steel involves using a flux-coated consumable electrode to create an electric arc between the electrode and the mild steel workpiece. The arc generates intense heat (around 3,000–6,000°C) that melts both the electrode and the base metal, forming a molten weld pool. As the weld cools, it solidifies into a strong joint.

- Teacher: OLIVIER MPARIBATENDA

1. SMAW on Aluminum

-

Overview: Lightweight, highly conductive; difficult to weld due to oxide layer.

-

Electrodes: 4043, 5356 (AC).

-

Key Points: AC current needed, preheat thick sections, avoid excessive heat to prevent burn-through.

-

Applications: Repairs and maintenance when TIG is not available.

2. SMAW on Stainless Steel

-

Overview: Corrosion-resistant, retains high-temperature strength.

-

Electrodes: 308L, 309L, 316L.

-

Key Points: Low heat input, clean surfaces, multi-pass for thick sections.

-

Applications: Chemical, food processing, and construction industries.

3. SMAW on Cast Iron

-

Overview: Brittle, high carbon; prone to cracking.

-

Electrodes: Nickel-based (ENi-CI, ENiFe-CI).

-

Key Points: Preheat 300–600°C, slow cooling, mostly for repair work.

-

Applications: Repairing machinery, engine blocks, pipes

- Teacher: OLIVIER MPARIBATENDA

The SMAW on Aluminium, Stainless Steel and Cast Iron (MATSA401) module provides learners with the theoretical knowledge and practical skills needed to perform Shielded Metal Arc Welding (SMAW) on a variety of metals. The course emphasizes workplace preparation, including material selection, tool and equipment setup, and the application of safety measures. Learners develop competence in welding different metals specifically aluminium, stainless steel, and cast iron by applying appropriate SMAW techniques, cutting methods, and defect correction procedures to ensure high-quality welds. The module also covers finishing operations, such as surface treatment, product protection, storage, workplace cleaning, and technical reporting. By the end of the course, students will be able to safely and effectively weld, finish, and maintain products made from various metals, following industrial standards of quality and safety.

- Teacher: NIYITEGEKA Jean Damascene

This specific module describes employable and practicable skills, knowledge and right attitudes required by the learner to prepare the workplace for SMAW aluminum, stainless and cast iron, weld the work piece and carry out finishing activities. The content provided in this course are package reserved for a learner pursuing TVET certificate IV in manufacturing technology, This course covers the principles, techniques, and safety practices required to perform Shielded Metal Arc Welding (SMAW) on aluminium, stainless steel, and cast iron. It emphasizes material-specific challenges, electrode selection, and proper welding procedures to achieve high-quality welds.

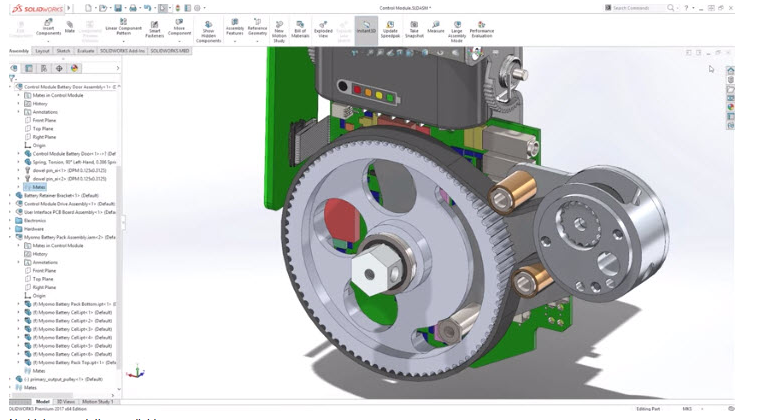

This learning outcome introduces students to SolidWorks, a 3D design software used in manufacturing and engineering. Students will learn how to open the software, understand the interface, and prepare the workspace for designing parts and assemblies

- Teacher: Illuminee BARAKAGWIRA

- Teacher: PHILIBERT GIRANEZA

- Teacher: ALBERT IMANIRAFASHA

- Teacher: RAISSA IRADUKUNDA

- Teacher: ELIE NSENGIMANA

- Teacher: NIYITEGEKA Patrick

SOLIDWORKS Design is a computer-aided design (CAD) software used to create, simulate, and visualize 2D and 3D models of products or mechanical parts. It allows engineers, designers, and manufacturers to design complex components, assemblies, and drawings with precision and efficiency. The software provides tools for sketching, modeling, rendering, and analysis, enabling users to test product performance, optimize designs, and prepare accurate technical documentation before production.

- Teacher: OLIVIER MPARIBATENDA

A SolidWorks design is a power full 3D CAD software design for mechanical parts, assemblies, and engineering drawings. It covers essentials like sketching, modeling, and drawing, plus advanced topics such as surface modeling and large assembly management. By the end, you will gain practical skills to create production-ready designs and optimize workflows in engineering and manufacturing.

- Teacher: Vedaste NDORUNKUNDIYE